scSTREAM

Features

scSTREAM thermo-fluid software has serviced the electronics and architectural industries for thirty years. The ever-evolving software is characterized by its overwhelmingly user-friendly interfaces and high speed processing. HeatDesigner is based on scSTREAM and is specially developed for thermal design of electronics products. HeatDesigner provides physical functions required only for thermal design with its simple interfaces and powerful computing performance.

Program Structure

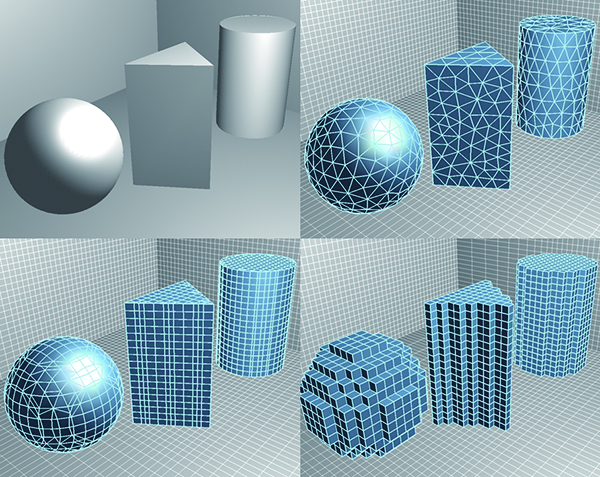

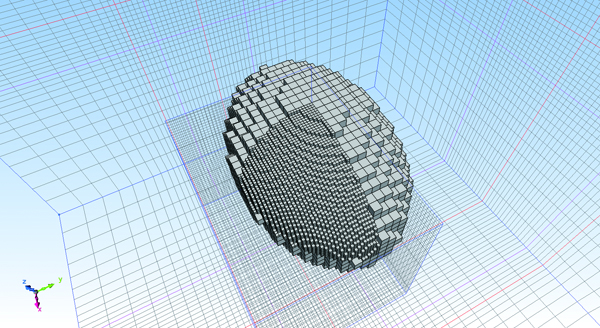

Various methods to represent shapes

The shape of a model to be analyzed can be represented by using the following methods: voxel method (slanted faces and curved faces are represented in cuboids), cut-cell method (the shape of a model created with a CAD tool can be represented more accurately), and finite element model method (a model of an arbitrary shape defined with unstructured mesh can be overlapped on a model defined with structured mesh to use the shape created with a CAD tool as is).

Large-scale calculation

In structured mesh, even a complicated model does not need to be modified almost at all and the shape or the scale of a model does not affect the difficulty of mesh generation. In addition, Solver performs a calculation at a high speed in parallel computing and achieves effective processing as the speed increases depending on the number of subdomains.

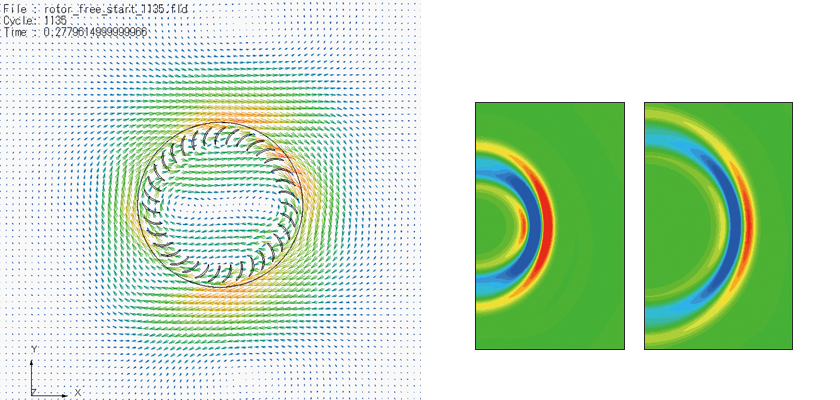

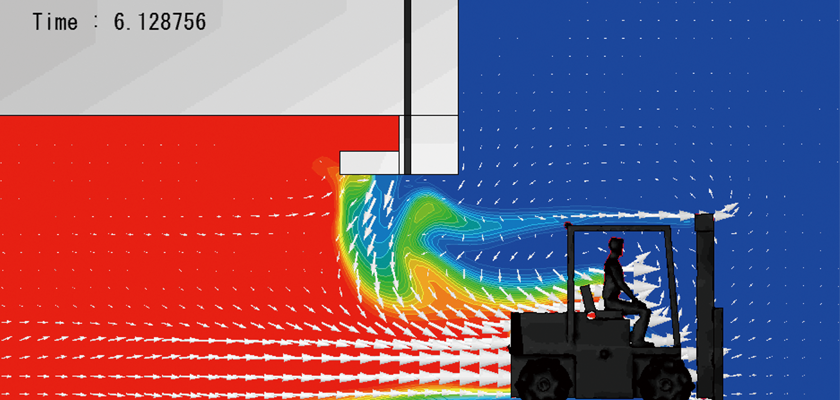

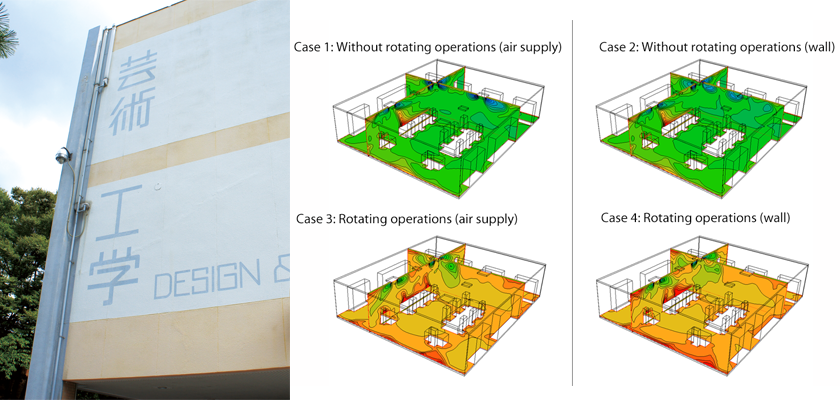

Moving objects

A flow generated by a moving rigid object can be calculated. Conditions including the motions of an object (translation, rotation, and elastic deformation), heat generation/absorption, and air supply/return can be set. The model of a moving object is created on another mesh. In this way, conditions such as the distance that the object moves are limited very little.

6-degree-of-freedom motion (6DOF)

The function can analyze passive translation and rotation of an object receiving a fluid force. A moving object is assumed to be a rigid body. Its movement whose maximum degree of freedom is six (3D translation + 3D rotation) can be solved. The function can simulate driftwood which is flowed by a force from water flow.

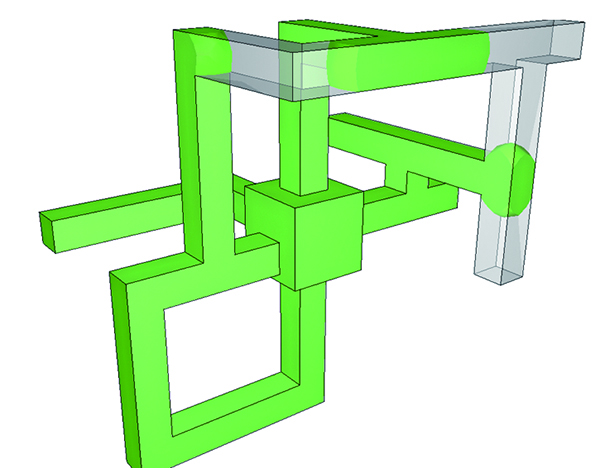

Multiblock

Mesh can be refined partially to represent a model shape more accurately and perform a calculation more efficiently.

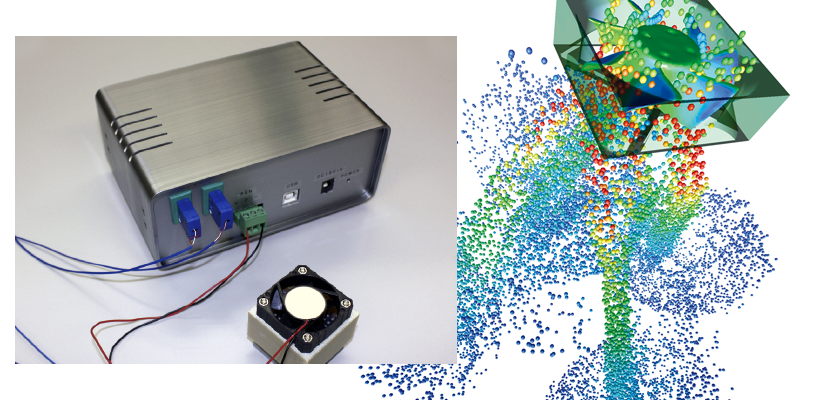

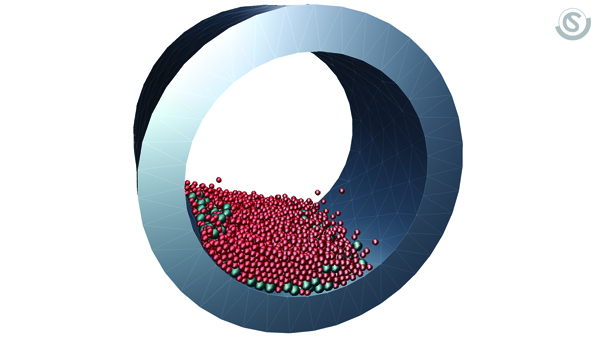

Discrete element method (DEM)

Multiphase analyses can be performed, which enables coupling of fluid analysis and flow analysis of particles.

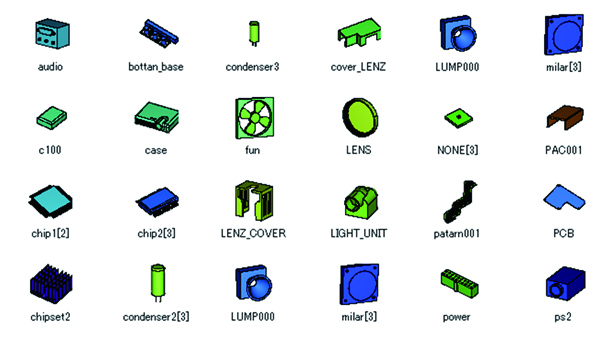

Part library

The shapes and conditions of frequently used parts can be registered. Conditions include the allocation position, material, and heat generation.

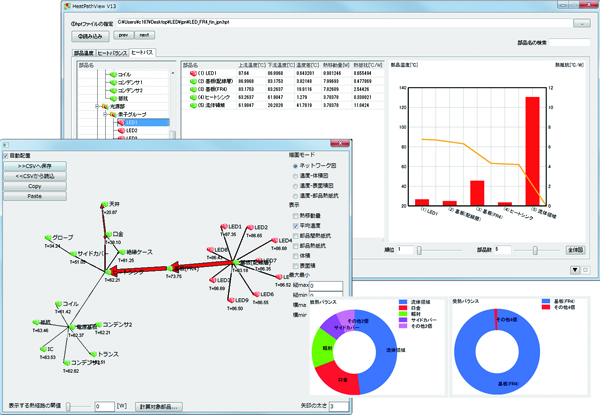

HeatPathView

The information on temperature of each part and a comprehensive amount of heat release obtained in post-processing of a general CFD analysis is not enough to know the heat path. HeatPathView displays heat paths and the amount of heat transfer in the whole computational domain in a diagram, a graph, and a table, allowing you to find the bottleneck of the heat paths easily.

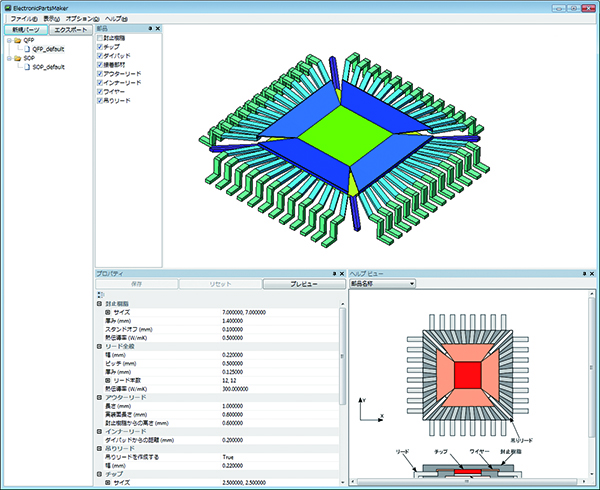

ElectronicPartsMaker

The tool can create detailed models of semiconductor packages including QFP, SOP, and BGA by specifying parameters, and simplified models using thermal resistor models such as DELPHI models and two-resistor models. Manufacturers of semiconductor packages can provide the data of semiconductor packages as thermal resistor models without releasing the inside information.

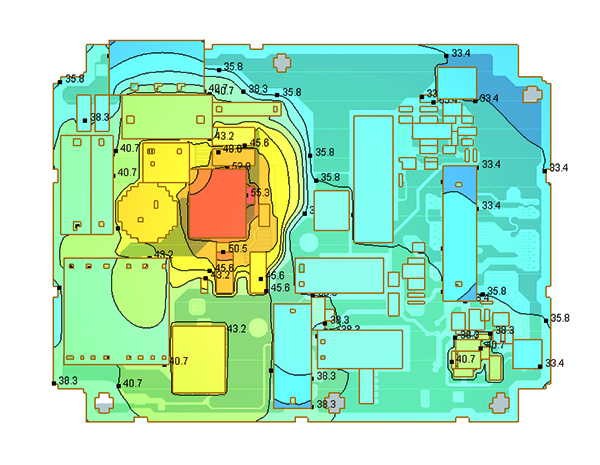

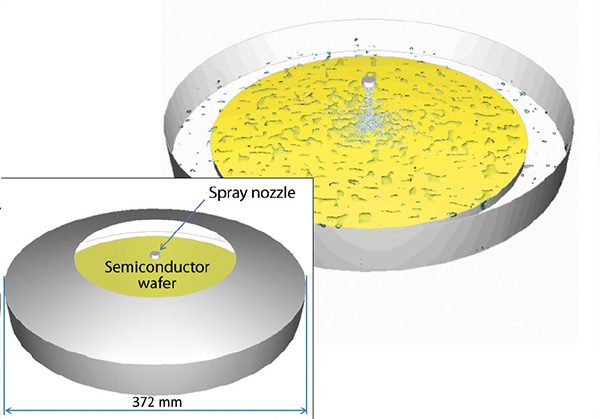

Reading wiring patterns

To calculate heat transfer conditions depending on wiring patterns of a printed circuit board (PCB) in detail, the module can read Gerber data output from an electric CAD tool and import the data as a model for a thermo-fluid analysis. By using Gerber data, a more realistic calculation result can be obtained with the consideration of heat transfer affected by an uneven wiring pattern.

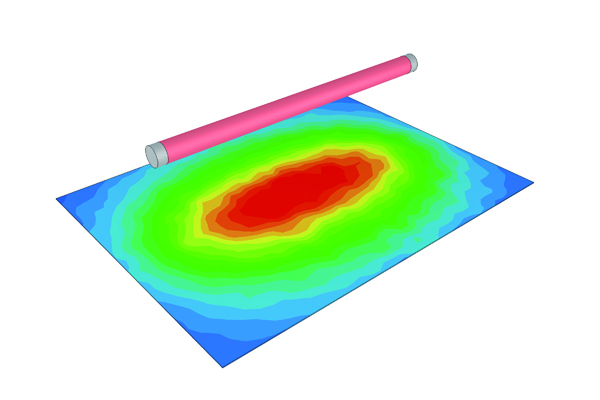

Radiation

Radiation heat transfer with the consideration of diffusion, reflection, transmission, refraction, and absorption can be calculated. VF (view factor) method and FLUX method*1 can be used. The lamp function can simulate radiant heat by a filament without detailed shape information of a lamp. In addition to the filament, laser beam and defective radiation specified by half-value angle can be used as a heat source model.

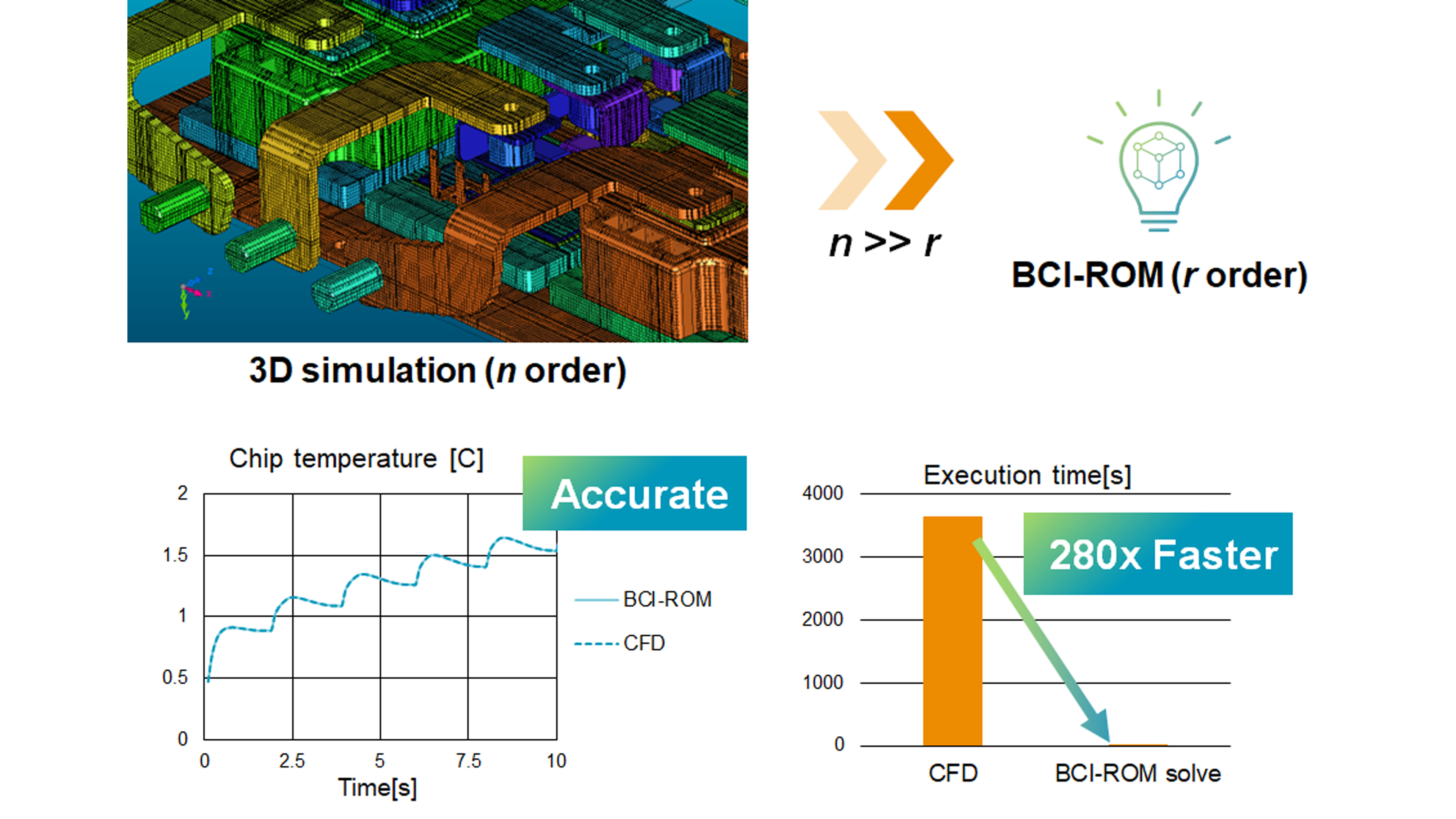

BCI-ROM (Boundary-Condition-Independent Reduced-Order Model)

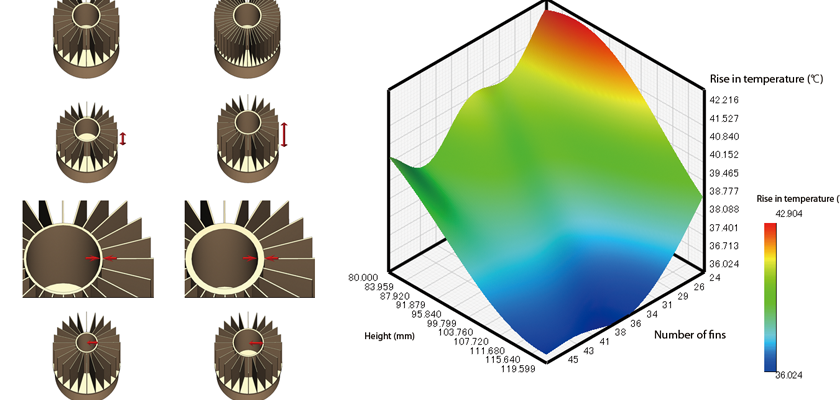

Automatically designing the optimal shape of components based on specified goals and constraints, this feature enhances the design process. Additionally, the integration with nTop significantly improves the workflow from design to manufacturing, enhancing both precision and efficiency. This allows engineering teams to quickly achieve high-performance designs.

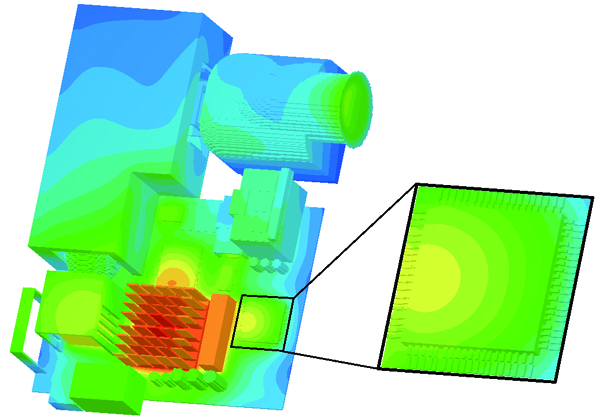

Topology Optimization

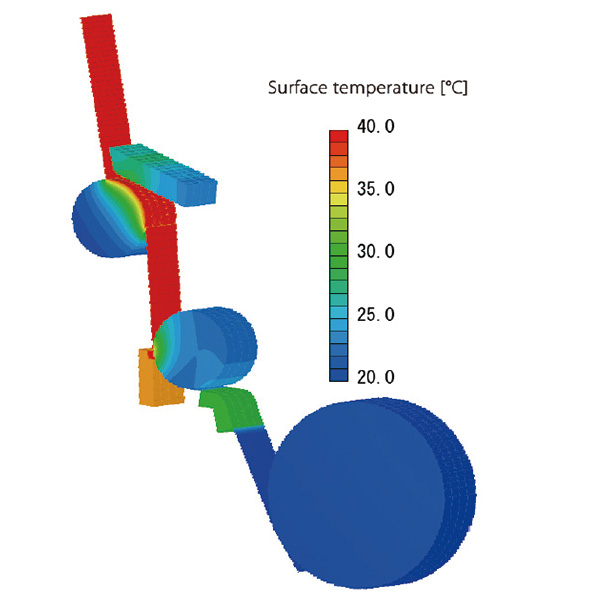

Automatically designing the optimal shape of components based on specified goals and constraints, this feature enhances the design process. Additionally, the integration with nTop significantly improves the workflow from design to manufacturing, enhancing both precision and efficiency. This allows engineering teams to quickly achieve high-performance designs.

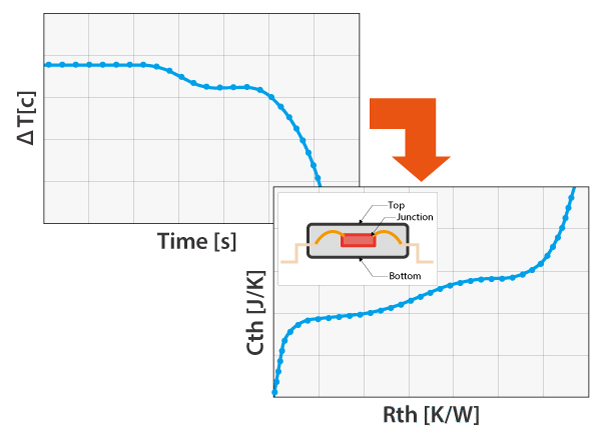

Using structure function from measurement

Modeling of electronic device is possible by converting result data of heat change over time used for transient heat resistance measurement*1 into structure function (thermal resistance - heat capacity characteristics). Accurate thermal model can be generated by comparing test and analysis data on the basis of structure function.

*1 Measurement device is not included

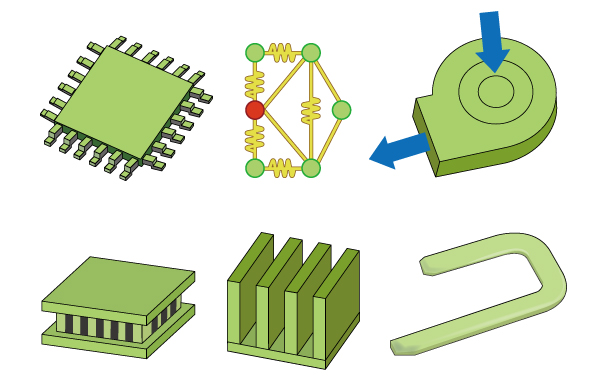

Electronic part model

A wide range of models are available that enable to easily achieve thermal design of printed circuit boards and electronical enclosures, which includes DELPHI (multi-resistor) model, Peltier device and heat pipes. It is possible to consider pressure loss characteristics using slits, and P-Q characteristics of fans using swirling component. Generated models can be added in library.

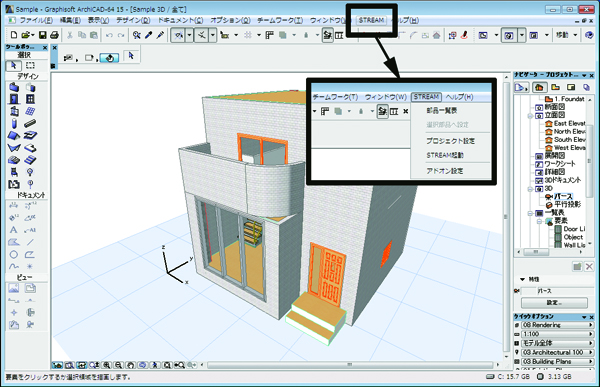

BIM

The software interface supports BIM 2.0. Autodesk® Revit® and GRAPHISOFT ARCHICAD have a direct interface (optional) through which a target part can be selected and the tree structure can be kept and simplified. In addition, the module can load files in IFC format, which is the BIM-standard format.

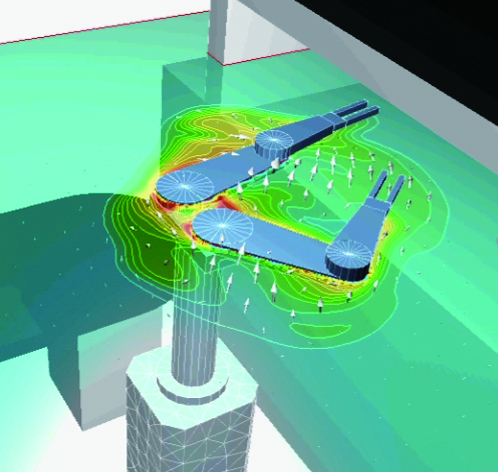

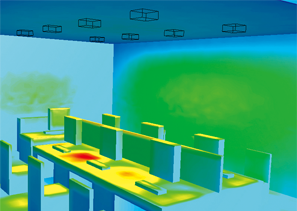

Air-conditioner parts (CFD parts)

The model shapes of parts frequently used for room air-conditioning can be imported. The models include ceiling cassettes, anemostat models, and linear diffusers. The software can import CFD part data, such as air supply characteristics, provided by SHASE*2. Various parameters can be set to simulate air-conditioning operation in addition to simple air heating and cooling.

*2 SHASE: Society of Heating, Air-Conditioning and Sanitary Engineers of Japan

Panel

(heat conduction / transfer / thermal transport)

Material properties and motion conditions can be applied to a panel having no thickness in model, which allows for heat conduction to other parts and heat dissipation to air. This enables the simulations of paper feeding and film drying processes, where thin objects move and go under heating repetitively.

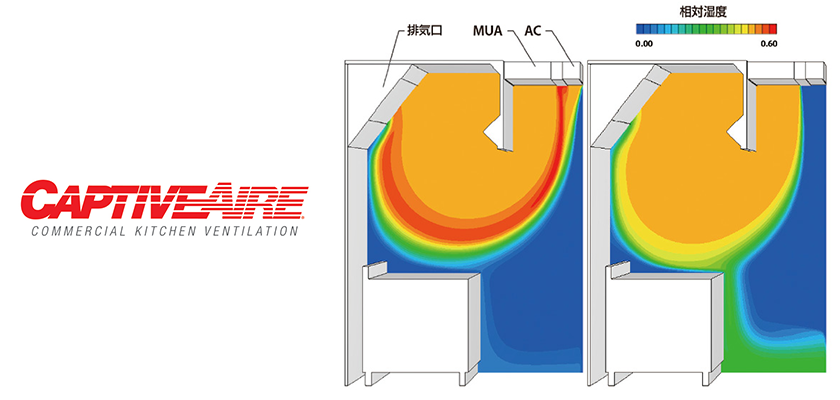

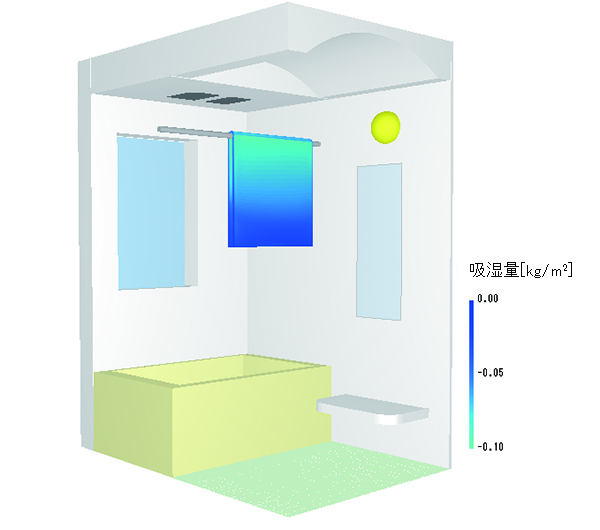

Humidity / dew condensation

The software can analyze humidity in the air. Dew condensation and evaporation on a wall surface due to temperature change can be considered and the amount of dew condensation and evaporation per time can be obtained. The software supports the analyses of moisture transfer inside a solid, and the function can be used to analyze a permeable object and dew condensation inside a part.

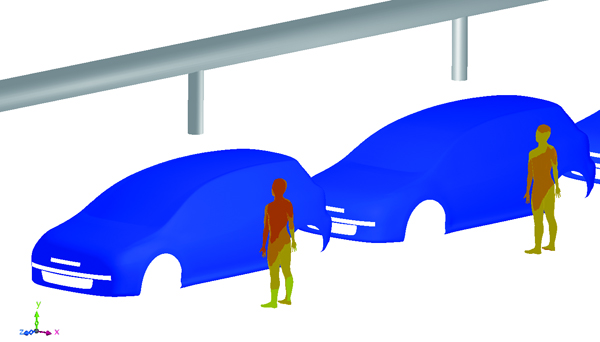

Thermal comfort, heat stress risk and ventilation efficiency indices

Comfort indices PMV and SET* can be derived from already obtained temperature, humidity, and MRT (Mean Radiant Temperature), as one of result-processing functions. WBGT (heat stress risk indices), and the scale for ventilation efficiency (SVE), of which some indices can be converted to a real time, can be set by one click, and the range of calculation area can be selected (for example, either one of two rooms).

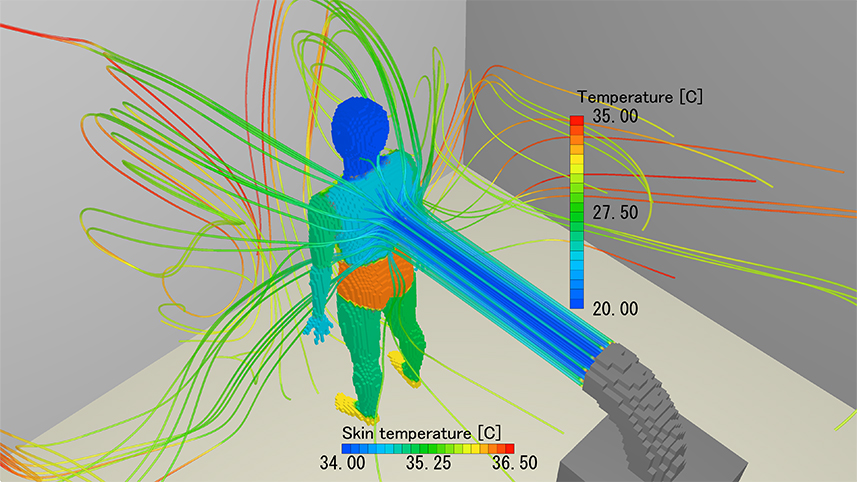

Joint System Thermoregulation Model (JOS)

Cradle CFD's Joint System Thermoregulation Model (JOS) in scSTREAM offers detailed insights into human thermal comfort in environments like vehicles and buildings. It evaluates skin temperature, perspiration effects, and thermal sensation, alongside heat and moisture release from bodies. These factors contribute to precise temperature and humidity calculations in thermo-fluid analysis.

* JOS-2, and JOS-3, developed by the Tanabe laboratory at Waseda University, et al., are introduced for the thermoregulation model

Illuminance analysis

The software can calculate illuminance of various types of light; for example, daylight through an opening of a building and artificial lighting with consideration of its directivity. Object surfaces such as walls are treated as diffusive reflection surfaces. In general, the larger an opening of a building is, the larger heat loss tends to be. By calculating the illuminance, the balance between heat and light can be examined collectively.

Solar radiation (ASHRAE, NEDO)

Climate data published by ASHRAE and NEDO is preset and can be used for condition setting. By entering arbitrary values of longitude, latitude, date, and time, the solar altitude and the azimuth angle of the sun at a specified location and time are calculated automatically. The effect of solar radiation can be examined in detail. Various parameters including absorption and reflectivity of solar radiation and materials which transmit light diffusely, such as frosted glass, can be set.

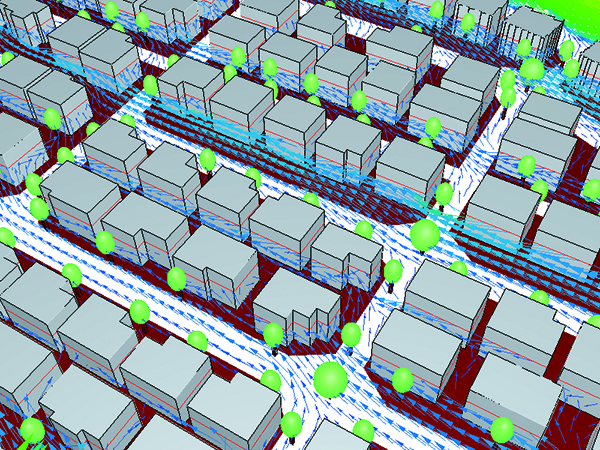

Plant canopy model (flow and heat)

Air resistance caused by plant canopy can be considered by setting the coefficient of friction and the leaf area density. For frequently used plants such as oak tree, their parameters are preset as the recommended values. The software also simulates the cooling effect by the latent heat of vaporization on a leaf surface by using the fixed temperature and setting the amount of absorbed heat. The function can be used for analyses of outdoor wind environment and heat island effect.

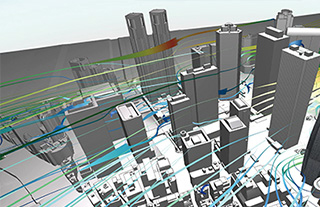

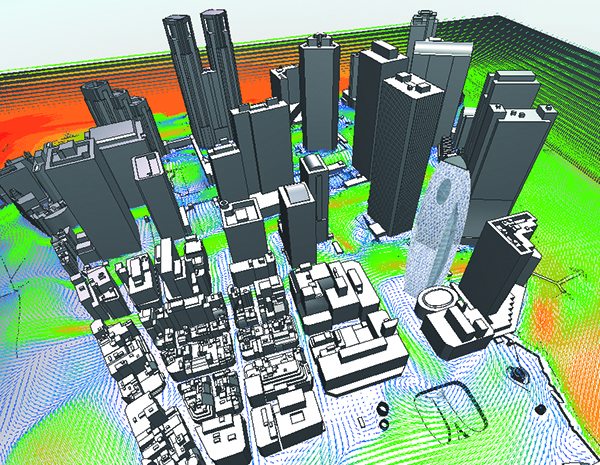

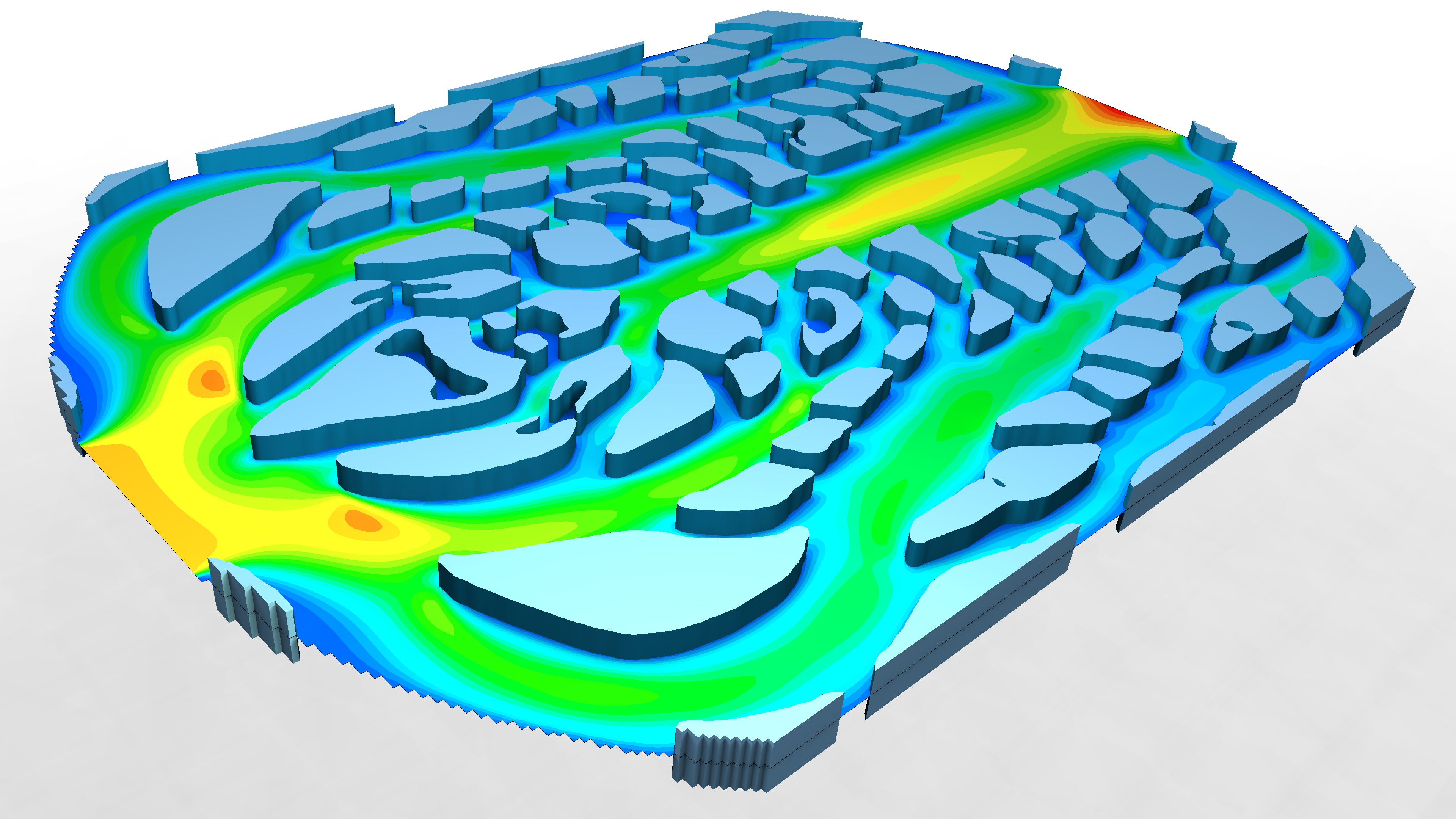

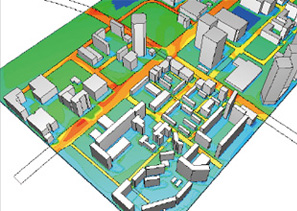

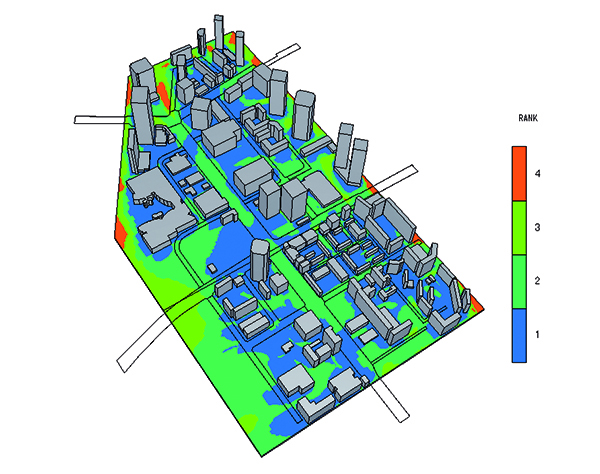

Windtool

(outdoor wind environment assessment tool)

This tool helps assess outdoor wind environment. The assessment criteria can be selected from the ones proposed by Murakami et al. and by Wind Engineering Institute. By specifying a base shape and parameters required for wind environment evaluation, the parameters for 16 directions are calculated and the wind environment is ranked automatically. Detailed distributions of air current and pressure per direction can be visualized.

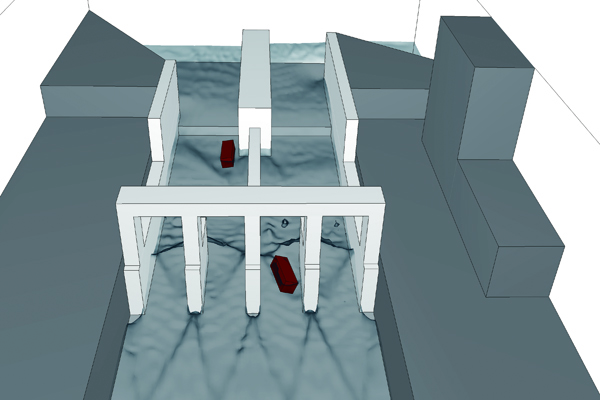

Mapping

When a target phenomenon is in a small range and the phenomenon is affected by a wide range of its surrounding area, analysis results of the surrounding area can be used for an analysis of the target phenomenon as boundary conditions to decrease the calculation load. To analyze only the inside of an enclosure for an electronic device highly affected by its outside, the analysis results of the outside can be used as boundary conditions.

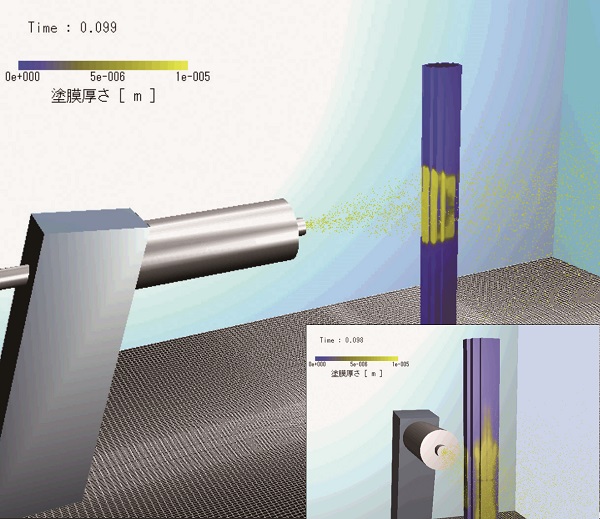

Electrostatic field

In addition to fluid force, the effect of an electrostatic field, which applies external force to charged particles, can be considered. By setting electric charge of particles and electric potential of a wall surface, the function can be used for analyses to consider area control of electrostatic coating. Velocity at which charged particles do not adhere on a wall surface can also be examined by using the function.

Flow of foaming resin

The software calculates the behavior of filling up an object with foaming resin, which is used as a heat insulator for houses and refrigerators. To examine speed and pressure of filling-up and the position for injecting the resin, the software simulates the behavior in 3D. The simulation can provide more pieces of information in shorter time than an actual measurement.

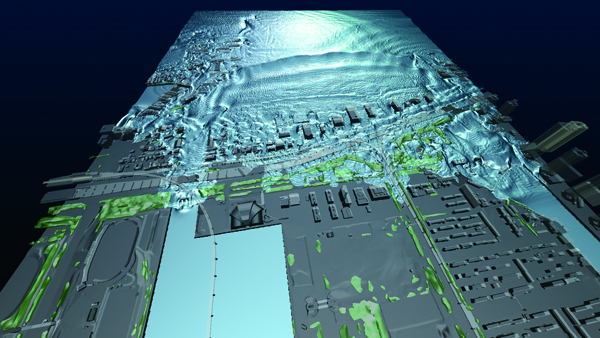

Free surface

The software calculates the shape of an interface between a gas and a liquid. Either MARS or VOF method can be used, and the calculation target phase can be selected: both gas and liquid, only gas, or only liquid. The function is useful in a wide range of fields: from an analysis of tsunami in the civil engineering and construction field to an analysis of soldering in the electronic device field.

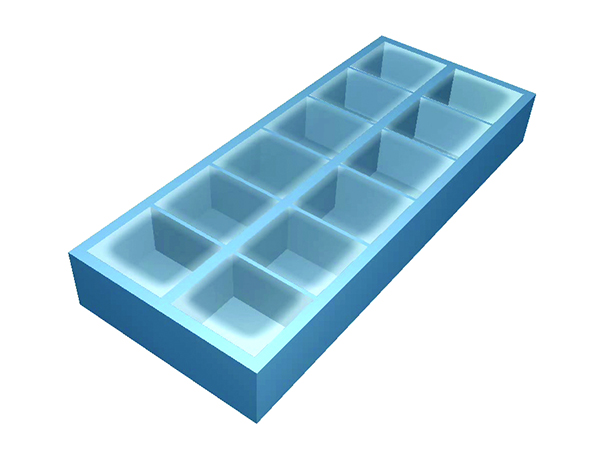

Solidification / melting

The phase change between fluid and solid, for example, water to ice and ice to water, can be considered. The following phenomena related to solidification/melting can be considered: change of flow affected by a solidified region, change of melting speed depending on the flow status, and latent heat at melting. A phenomenon that water in an ice maker becomes ice can be simulated using the function.

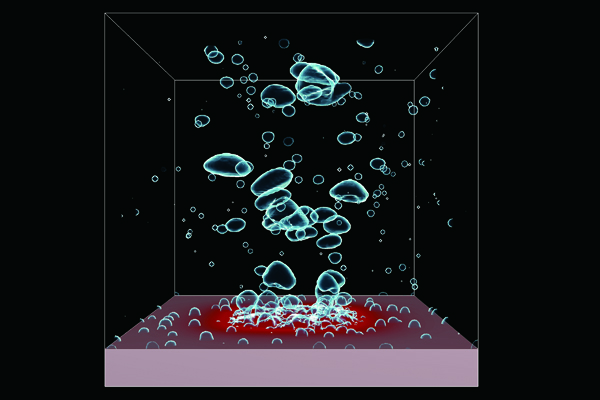

Boiling / condensation

(bubble nucleation, bubble growth / condensation)

With the function, the user can analyze a boiling flow, which is a gas-liquid two-phase flow caused by temperature difference between a liquid and a heat conduction surface. A boiling flow is analyzed as a free surface analysis using MARS method, and latent heat generation and volume change due to bubble growth / condensation are considered using phase change model.

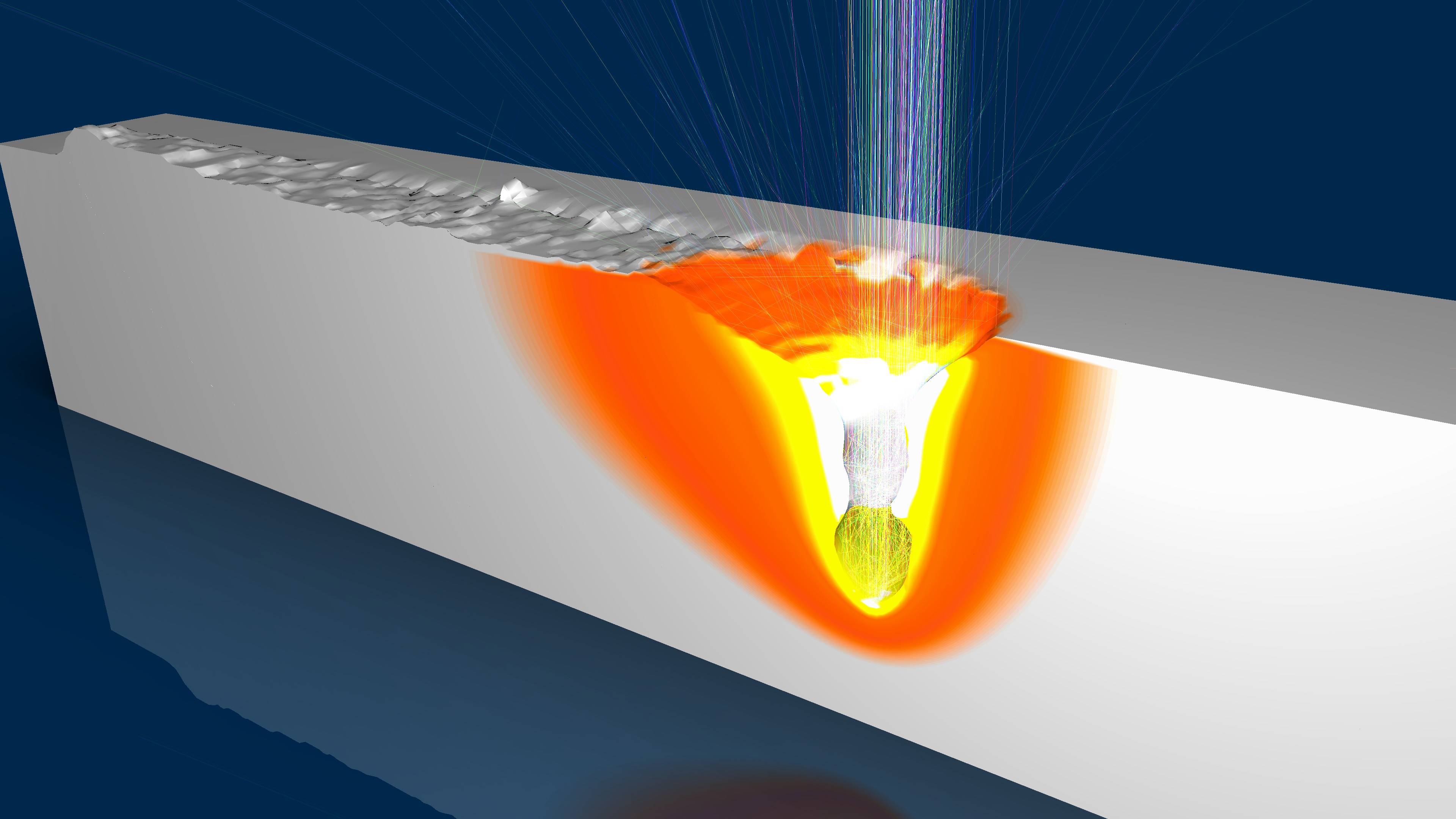

Laser Beam Welding

Keyhole laser welding is a capability in scSTREAM. It supports the welding of similar materials. This capability

predicts the penetration profile, keyhole behaviour, and heat-affected zone (HAZ). Optimal welding conditions are studied by evaluating changes in laser power, travel speed, beam size, and welding trajectory. The calculated weld penetration profile can be exported and used in structural analysis.

Particle tracking

The software simulates the behavior of particles depending on their characteristics (diameter, density, and sedimentation speed) and action/reaction between particles and a fluid. This includes sedimentation due to gravity, inertial force for mass particles, and movement due to electrostatic force, liquefaction at adhering on a wall surface, evaporation and latent heat, the behavior as bubbles in a liquid for charged particles.