Tomo PE Jp Office

Tomo PE Jp Office Choose MSC Cradle CFD to Improve their CFD Modeling and Hypersonic Analysis Proces

SC/Tetra, a thermo-fluid simulation Software from Cradle is an indispensable analysis tool for Tomo PE Jp Office, a consulting services company that focuses on innovative CFD technologies. We interviewed the CEO, Teruhiko Tomohiro. He has been involved in research and development of various fan types from both aspects of experiments and simulation for many years. We also asked him about the recent analysis examples and expectations for CFD tools.

Tomo PE Jp Office is a technology driven consulting firm that is focused on design and development of fans. Proficient in innovative CFD technology, the company also provides consulting services and conducts lectures on advanced applications of CFD.

Teruhiko Tomohiro the CEO told us: “CFD is used in various fields. Although we can easily obtain analysis results, knowing ‘how to’ interpret the results can be challenging. Our office advises customers on solving these questions”.

Picture 1: Mr. Teruhiko Tomohiro, Professional Engineer (Mechanical Engineering, Information Engineering), Tomo PE Jp Office

Before starting his own company in 2011, Mr. Tomohiro worked with Panasonic for 30 years. During this time, his work has focused upon research and development of various types of products such as blowers, air conditioners, kerosene fan heaters, cooking appliances, and fuel cells, through combinational approach of simulations, prototyping, and testing. He has conducted several CFD analysis models to research the aerodynamic and noise performance of axial-flow, centrifugal, and cross-flow fans, and developed an in-house software tool for fan design.

With a profound background in CFD technology, Mr. Tomohiro was one of the first users of scSTREAM, a structured mesh thermo-fluid analysis software that was just released at that time. Later on, around 2000, he started using SC/Tetra, an unstructured mesh thermo- fluid analysis software. Since founding own office, SC/Tetra has been the essential tool for fan development projects in his business.

Unpredictable Performance of Cross-Flow Fans

Over the past years, Mr. Tomohiro and his team have provided a full range of CFD studies in support of their development process for cross-flow fans as well as basic propeller fans. Additionally, the team is involved in projects that simulate the ultrasonic wave propagation in a flow field.

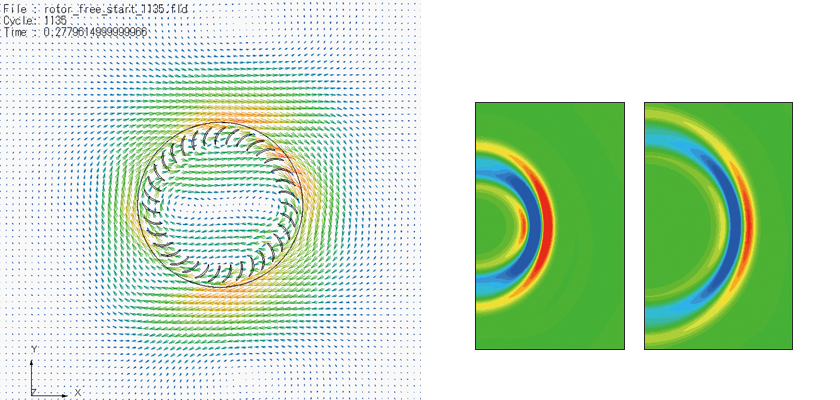

Figure 1 shows simulation results of a propeller fan. Most these studies investigate the effects of vortices (around the blade tips) on fan noise and performance. Figure 3 illustrates the wing tip vortex of a fan blade.

Figure 1: Analysis example of a propeller fan

In recent years the countermeasures against performance have decreased.

As such, noise caused by vortices at the tip of a propeller receive more attention

Cross flow fans are widely used throughout the HVAC industry as well as household air conditioners. Designed to prevent components from overheating, these special fans significantly differ from the ordinary centrifugal fans.

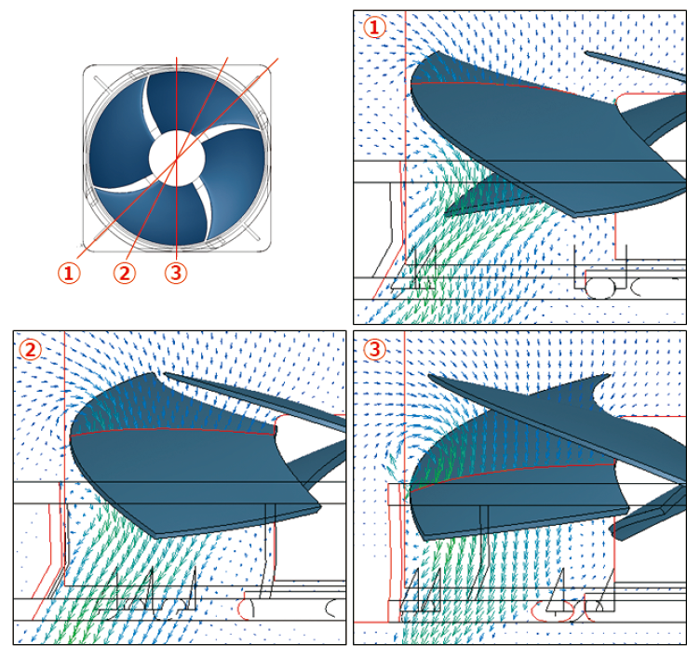

Cross flow fans consist of a long and thin cylindrical structure that blows wide uniform air flow. Air enters the front and top faces of the air conditioner and is blown into the cylinder through a curved impeller. Finally, the air flows out from the bottom side of the impeller (Figure 2).

Figure 2 Airflow mechanism of cross-flow fans. Flow passing through the impeller twice with eccentric vortice

Three main characteristics of a cross-flow fan include the flow behavior, the eccentric vortices generated inside of each part, and the number of blades. The name of cross-flow fan is originated from its characteristics that air comes out cross the whole with of the impeller (Figure 2). The generation of penetrating flow and eccentric vortex is a distinctive characteristic of cross flow fan. As a result, air transfers through and across impeller; the name ‘cross flow fan’ in fact derived from this phenomenon.

For the peculiarity of a cross-flow fan, Mr. Tomohiro says “The theoretical methods for design of propeller fans and turbo fans have already been established. However, as for cross-flow fans, there is no such theory defined.” In other words, some consumer electronic makers have released air conditioners that use cross-flow fans, but they have used the trial and error methods to come up with their designs.

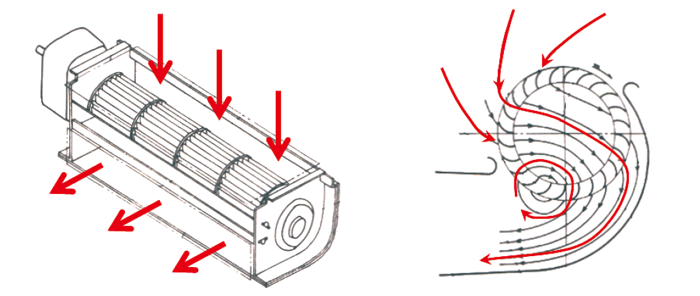

Figure 3 shows the simulation results of the flow, where the impeller of a cross-flow fan was solely used. The impeller starts to rotate in the state of no wind and then the vortices are generated. Air partially flows into the cylinder and gets stronger as it passes through many points. The flows then merge together to generate one strong vortex. We can observe that the speed at which the resultant vortex rotates around the impeller is lower than the speed of the impeller itself.

Figure 3: Change of a flow field when only the impeller of a cross-flow fan rotates.Multiple flows pass though the cylinder and merge to eventually form one fluid flow. The speed of the resultant flow is lower than the rotational speed of the fan. Color bar indicates the size of flow velocity.

As demonstrated, the flow field that a cross-flow fan generates is unstable. Generally, air conditioners have a container that is attached around the unstable flow field to make it stable. We can easily predict this phenomenon using a CFD simulation tool. “In a situation like this, we can only observe the air that flows through the impeller. Without using simulations, we are not able to capture the details on the fluid flows, how they are merged to eventually form a rotating force, or know when and why the vortices are generated.”

Several decades have passed after the first air conditioner was made and to date, the high performance ACs are designed based on testing and experiments.

After joining Panasonic, Mr. Tomohiro was first assigned to work on the design and development process of cross-flow fans. He is also experienced in flow measurements.

We can qualitatively predict the performance level of propeller and turbo fans, based on parameters such as scale and angle of each part or the number of blades.

However, as Mr. Tomohiro says “A cross-flow fan has very unique characteristics and therefore, detailed research on this subject is not available. I think we will be able to predict the performance of cross-flow fans based on theories, if more research is to be made.”

Predicting Ultrasonic Waves in a Flow Field

Other than development of fans, as a secondary project, Mr. Tomohiro studies the propagation of ultrasonic waves using fluid analysis tools. Although several tools are available for analysis of ultrasonic waves, most of them do not account for flows, especially for wave propagation in a solid.

Sounds are compression waves that move through a medium. Knowing this, Mr. Tomohiro believed that commercially available CFD tools are capable of solving the problem of ultrasonic waves in a compressible fluid analysis.

“Experiments were not enough to know how ultrasonic waves change while they propagate in a flow, and how the change affects ultrasonic waves if a flow changes.” Mr. Tomohiro continues: “Although simulation accuracy is necessary, I want to use CFD tools for qualitative approaches, for example to know what flow change influences the propagation of ultrasonic waves.”

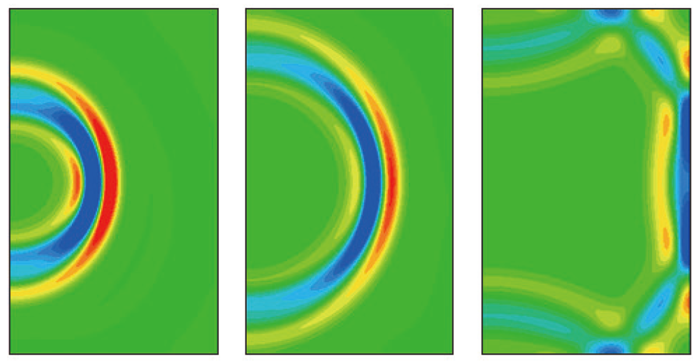

Figure 4 shows a pressure contour map of ultrasonic waves traveling through a gas fluid enclosed in a chamber with square walls. A transient analysis without any flow was performed at the frequency of 40 kHz. The vibrating wall regions are considered as the source condition for ultrasonic waves, resulting in generation of fluid inflow and outflow. From the figure, we can clearly observe that the wave propagation, reflection, and diffraction are well predicted using simulation.

Figure 4: Propagation of ultrasonic waves in a fluid A transient analysis has been performed at the ultrasonic wave frequency of 40 kHz, to simulate the generation of ultrasonic waves. The inflow and outflow of the fluid are generated from the vibrating wall regions

Mr Tomohiro and his team faced some challenges when using CFD tools to simulate ultrasonic wave propagation: “I do not know what is correct because I use the tool in a specific way.” Mr. Tomohiro says. The implementation of commercial CFD tools to study sound dates back to early 2000s.

According to Mr. Tomohiro “CFD tools in the past were not designed to be used for ultrasonic wave analyses. The pressure change of sound is much smaller than that of a flow. As such, a CFD program needs to have the appropriate capability to accurately capture the change. Today, we can obtain qualitative results to some extent. For now, I cannot say the commercial tools are useful enough for aerodynamic noise simulations. However, I want to make it practical.”

Functions and Accuracy Enough for Analysis Task

Utilizing SC/Tetra has helped Mr. Tomohiro and his team to reduce the number of experiments and obtain a better understanding of the fluid sound sources. “As far as my business concerns, SC/Tetra has useful functions and provides high accuracy.” Before starting his own company, Mr. Tomohiro performed both experiments and simulations, but he has no environment for experiments now. Therefore, the team inevitably uses SC/Tetra for their consulting projects. In a sense, SC/Tetra is very helpful.

Back in 2016 Software Cradle released scFLOW, a new thermo-fluid analysis software equipped with polyhedral mesh. scFLOW is a progressive version of SC/Tetra that provides a more advanced solver with higher calculation speeds.

AI Support for Large-Scale CFD Calculations

As for the future of CFD tools, the next big trend is to support automation process for large-scale calculations. “The number of elements increases to several thousand or even millions when working with complex CFD models. It is hard to even load or output data, even if a high-performance computer is used. In addition, new methods must be taken into account. In some cases, analysis results can be compressed.” Mr. Tomohiro says.

He also believes that utilizing AI can improve the efficiency of data analysis process. “Many engineers are interested to decrease resistance and loss in fluid flow of a fan or a duct. We can display a region with large loss from the newly obtained analysis data or use different colors to identify the causes of loss by learning from past analysis results. CFD tools that can that use AI will be very useful for design engineers in the development site.”

Professionals Who Know the Actual Design Process as well as Simulations

Mr. Tomohiro hopes to see more engineers that are proficient in CFD modeling and simulations while experienced in testing and design process. “Most software companies offer engineering advice to the users and are experts in running CFD simulations. However, those that are involved in the actual design process or testing stage, can greatly improve the quality of services provided to their customers.” Some users only focus on running simulations without getting involved in the design process. “The services provided by the vendors who know the design site will be very helpful for such users, as well”

Although Tomo PE Jp Office works on many CFD related subjects, their main focus is on development of various types of fans. They have interesting case examples and expectations for the evolution of scFLOW. Software Cradle will continue to implement innovative CFD functions in respond to these expectations.

Tomo PE Jp Office

- Established: April, 2011

- Business: Consulting on research, development, and design of fans, consulting on computational fluid analyses

- President & CEO: Teruhiko Tomohiro

- Head Office: Ikoma City, Nara, Japan

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of January 31, 2017 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download