Case study: Developer

New order | Old order

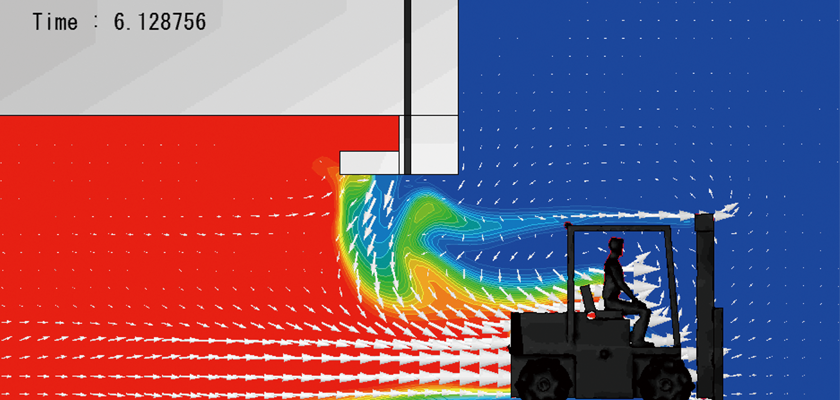

Optimization: Tool for Fast, Cost-Efficient Analysis

Thermoregulation Model JOS Function

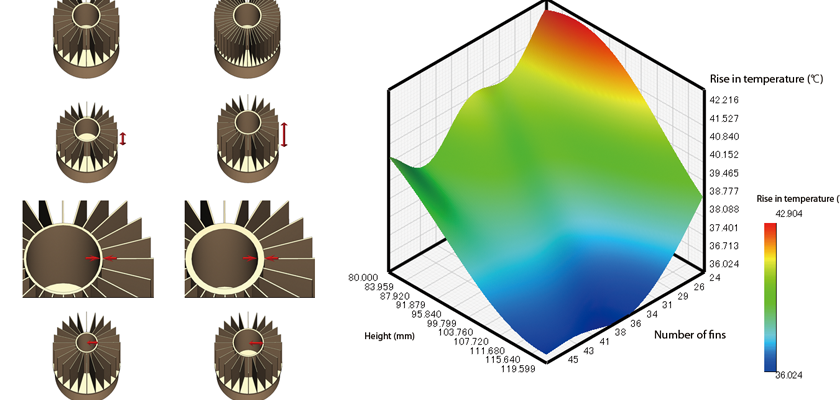

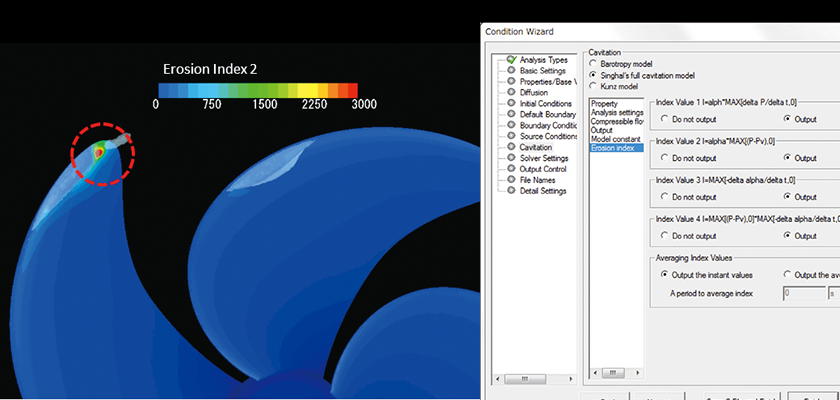

Development of the Cavitating Flow Analysis Function

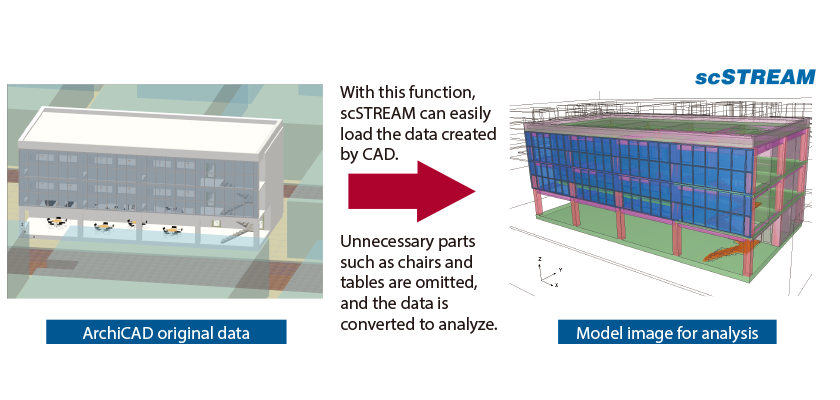

The Story Behind the Development of scSTREAM Launcher (Autodesk® Revit®) and Launcher (ARCHICAD)

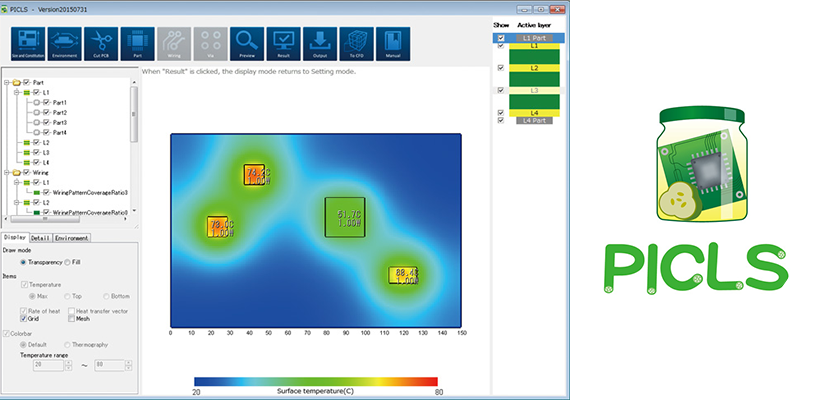

Development of PICLS

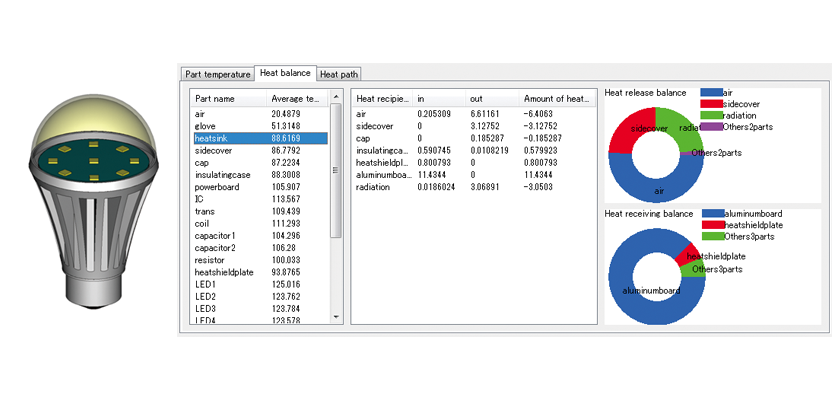

HeatPathView: Development Background

Picked Up Contents

Whitepaper

Turbocharging CFD with Katana

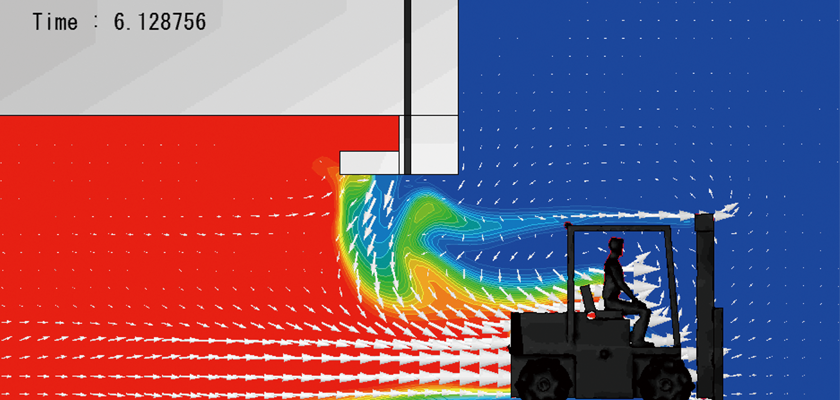

Unleashing cutting-edge computational fluid dynamics from Japan