Hitachi Mito Engineering Co., Ltd.

- Real-time Solutions for Thermal Problems

- Key to Success is a Workplace Environment Where Design Engineers Can Promptly Implement Their Ideas

Hitachi Mito Engineering provides engineering support for the development of elevators and various industrial products. To minimize tasks and improve process efficiency during the early phases of development, they conduct simulations for thermal design processes using analysis tools developed by Software Cradle. Hitachi Mito Engineering has been a very successful company. This narrated interview will provide insight about how they achieve steady growth while incorporating the latest technology and consistently building on their accumulated experiences.

Picture 1: Mr. Naohisa Usui, Circuit System Design Group, Department of Control System Design, Hitachi Mito Engineering Co., Ltd.

Hitachi Mito Engineering provides engineering support for a diverse range of industrial products. These include essential transport infrastructure systems such as elevators, escalators and railway. Manufacturing elevators and escalators requires standardized manufacturing techniques and processes. However, they can also include customization according to client requests and building requirements. Hitachi Mito Engineering has been providing high quality products that are efficiently designed using the latest digital engineering technologies, manufactured in contemporary facilities, and thoroughly tested and evaluated. As a result, their products achieve very high customer satisfaction. Due to the need for these tasks to run smoothly, Hitachi Mito Engineering has always been quick to adopt the latest technologies and utilize the various tools, inspection devices, and IT systems. This includes introducing thermal analysis tools developed by Software Cradle.

Total Thermal Solution for Design Engineering Tasks

“I have worked with circuit board designs, structural designs, and CAE (Computer Aided Engineering) tools that are vital for product development,” says Mr. Naohisa Usui, an engineer in the Circuit System Design Group at Hitachi Mito Engineering (Picture 1). His division mainly designs the printed circuit boards (PCBs) used in the company products. As a thermal analyst, Mr. Usui performs circuit design, board design, and thermal analyses as part of the PCB design process. Although Mr. Usui is responsible for resolving the thermal problems faced by the design engineers, he reveals that finding the best solution process has not been easy. “Everything was new to me when I was first assigned to CAE tasks. It took me hours just to generate mesh elements. Back then, we were using other finite element software and facing a lot of problems. That was when we came across Software Cradle products,” recalls Mr. Usui.

Partnership as a Critical Factor

Software Cradle’s HeatDesigner entirely changed Mr. Usui’s views on thermal analyses. Having compared other analysis tools, Mr. Usui was impressed with the mesh generation capability and calculation speed of HeatDesigner. It offered solutions to all the immediate problems they were facing. High quality support was another decisive factor. Mr. Usui was looking for a software vendor that would provide excellent engineering support through honest and sincere discussions. He regards the technical exchanges with Software Cradle engineers with a very high level of trust. “The fact that Software Cradle is a reliable Japanese software developer helped us make the decision to use HeatDesigner. After we introduced the software in the company, our engineers had a number of requests. According to their requirements, Software Cradle engineers added functions that enabled us to analyze Gerber data and slanted fans. It was very helpful,” says Mr. Usui.

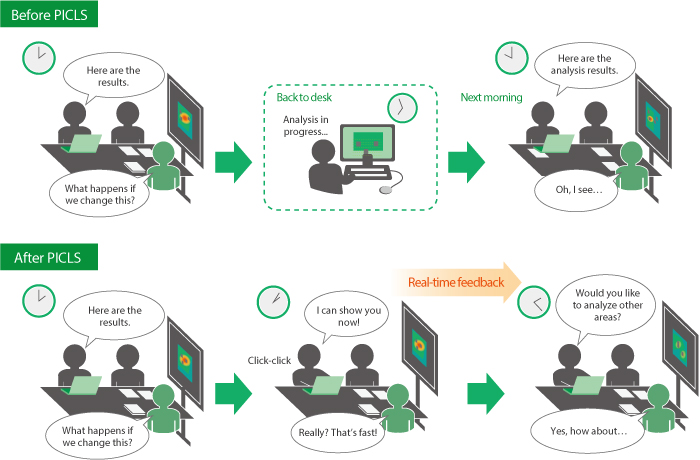

Fig 1: Conceptual illustration of design review changes

PICLS - Development Based on the Voice of the Design Engineer

Mr. Usui now focuses on thermal analysis support for design engineers through the use of PICLS (refer to the last page for more about PICLS). The development of PICLS was closely related to exchange between Mr. Usui and Software Cradle. “In talking to our design engineers, I thought it would have been useful if I had been able to show analysis results in real time and suggest possible solutions on the spot while I'm talking to the engineers about their thermal design problems (Fig 1). Although we conduct detailed thermal fluid analyses using scSTREAM in later processes, I felt the strong need to allow the design engineers to evaluate different ideas early in the design phase,” says Mr. Usui. Software Cradle engineers agreed, and realized the growing significance of analytically assessing preliminary concepts early in the design process. After several discussions, Software Cradle decided to develop PICLS.

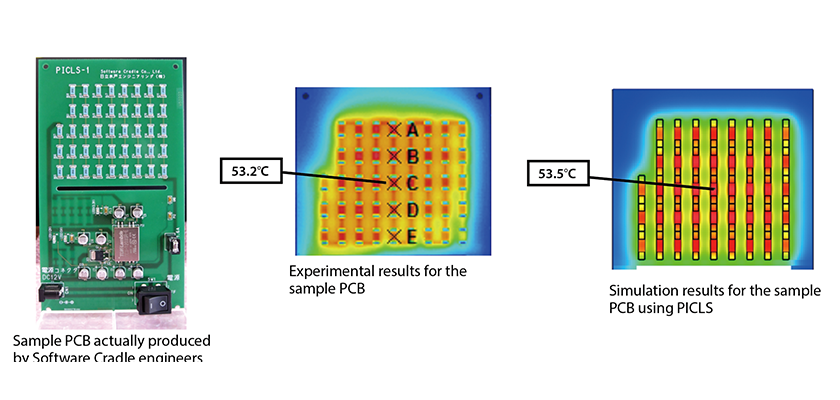

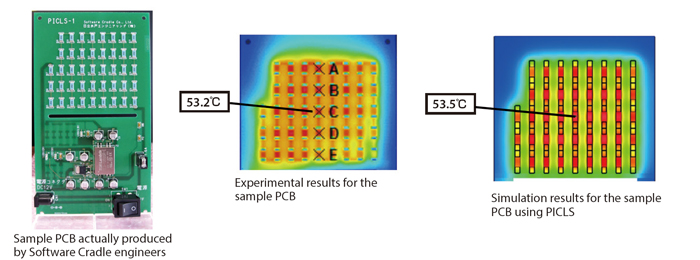

Fig 2: Producing sample PCB, conducting experiments, and comparing with simulation results

During PICLS development, Software Cradle engineers actually designed PCBs in order to understand how the tool could be practically used by design engineers. This included attending lectures on the basics of PCBs, inputting wire data, producing a sample PCB, and undertaking test experiments (Fig 2). Based on the hands-on experience and Mr. Usui’s suggestions, Software Cradle engineers investigated methods for enhancing software approachability to make analysis model generation easier.

High Operability as First Priority

When making suggestions and requests to the Software Cradle engineers, Mr. Usui remembered to also include the opinions of non-CAE experts. He talked to design engineers who were not familiar with CAE and asked about their thoughts. As a result, Mr. Usui found that the biggest challenge the design engineers faced was “to identify a way to determine how much the temperature can be lowered by reallocating components.” To solve this problem, Mr. Usui thought the analysis tool must satisfy the following conditions: model generation is easy, processing analysis results is seamless, and changes in heat transfer and temperature distribution can be analyzed real-time. Mr. Usui understood that the software would be acknowledged as a practical thermal analysis tool only when it satisfied these requirements. This meant the software must be capable of real time component relocations while reviewing thermal analysis results. This would enable design engineers to try different thermal design ideas on the spot. If developed, this capability would be revolutionary. “At the beginning I was skeptical about whether this could all be possible. But after seeing the development process, my doubt turned to conviction. I became excited with the expectation of witnessing the creation of a genuinely practical tool for design engineers,” says Mr. Usui.

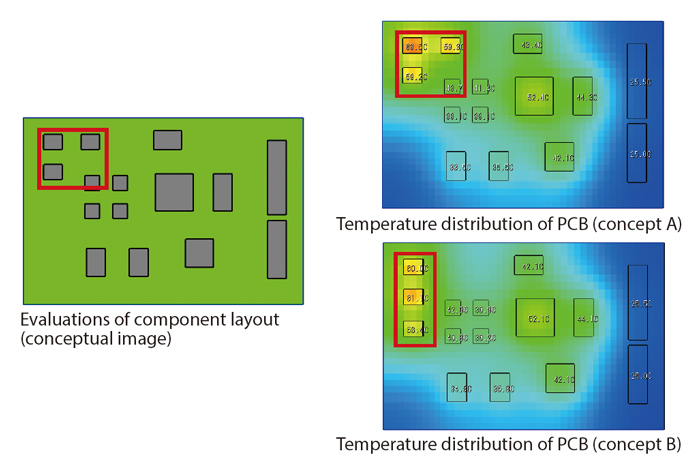

Fig 3: Conceptual image of component layout evaluations using PICLS

Benefits of Using PICLS for Design Engineers

In 2015, PICLS development was completed. PICLS is now used by design engineers. It did not take long for the tool to be applied to actual tasks. As soon as Mr. Usui introduced PICLS to the design engineers everyone was amazed at its capabilities. Design engineers were impressed with the ability to check heat transfer and evaluate changes in temperature distribution in real-time. This convinced them of the tool's effectiveness (Fig 3). This contrasted with earlier realizations that many engineers in the company had dismissed thermal analysis software as too advanced, and the tools as being unapproachable. The greatest benefit of PICLS is its simple operability. As a result, Hitachi Mito Engineering was able to front-load their CAE processes. This minimized analysis tasks and shortened evaluation time. Both led to faster development in the design phase. Development speed accelerated dramatically. Identifying thermal problems early in the design phase and collaboratively developing solutions with the CAE analysts meant more efficient product development. The expectation was high within the company. Hitachi Mito Engineering is now considering improving process quality, which can be dependent on the quality of each analyst's skills, by improving internal training for design engineers. The content of the training could be based on the accumulated experiences by the engineering staff. As more design engineers become active PICLS users, the benefits will grow even more.

Further Ambitions

Mr. Usui says that when he is assessing a design, he can occasionally identify the cause of design problems without having to conduct an actual thermal analysis. Even so, showing the actual analysis results is more effective for helping the design engineers to increase their understanding compared to merely speculating. Although PICLS is still in the process of being fully implemented into the design process, Mr. Usui has further ambitions. “I’m hoping to encourage design engineers to use PICLS as much as possible so that they can conduct PCB thermal analyses on their own. Not only that, I’m hoping to see scSTREAM being used to conduct thermal fluid analyses of Gerber data, two-phase analyses using the MARS (Multi-interface Advection and Reconstruction Solver) method, condensation, solar radiation, and Joule heat analyses,” says Mr. Usui.

Future Prospect of Thermal Analyses

Mr. Usui, who has substantial practical experience as a thermal analyst, comments on the future prospect of thermal analyses: “it is to capture thermal design ideas and suggestions from those who are affected by using the tool. These include our clients, design engineers, and everyone that is involved in the development of the product. If someone suggests that there is a risk with junction temperature, we should undertake thermal analyses and investigate right away. We must avoid fatal thermal problems late in the cycle that could have been avoided if we had conducted thermal analyses earlier in the process.” Mr. Usui finds it fulfilling to tackle challenging thermal problems. “The sense of achievement is huge when I am able to solve difficult thermal problems. I consider it my mission to help design engineers by solving thermal problems. The true worth of a CAE analyst is proved when facing and solving these challenges. That is why I welcome any challenge, and I appreciate the support provided by Software Cradle engineers. We work side by side to solve these problems,” says Mr. Usui.

Drawing from his own thermal analysis experiences, Mr. Usui is eager to be involved with training. “I strongly doubt that we could train analysts just by providing software. We need to train our own thermal analysis experts and request technical support from Software Cradle as needed,” says Mr. Usui. Certainly Hitachi Mito Engineering will continue to pass on their thermal analysis experiences and knowledge to their engineers. Software Cradle products are expected to play a significant role in their product development processes.

Hitachi Mito Engineering Co., Ltd.

- Founded: March 18, 1967

- Businesses: Design, inspection, manufacturing, and engineering support for elevators and escalators, railway transport system, building systems, and other industrial products

- Representative: Kunihisa Saito, President and CEO

- Location: Hitachinaka-shi, Ibaraki, Japan

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of June 1, 2015 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download