SAXA Inc.

Key to Success: Creating an environment in which engineers can objectively evaluate analysis results

SAXA Inc. (hereinafter SAXA) is a development company of business phone systems and network equipment and has obtained significant results using the software. SAXA launched a working group specializing in thermal design, and then in-house rules were prepared for selecting and utilizing software product before adopting HeatDesigner. 'HeatDesigner' is developed by Software Cradle and is one of the major thermo-fluid analysis software for electronic devices. And the company has achieved zero production rework in only one year. This time, we interviewed a SAXA staff about how they made full use of the software and what lies behind their success.

Noriaki Suzuki, Mechanism development department, Engineer, SAXA Development office

Noriaki Suzuki, Mechanism development department, Engineer, SAXA Development office

SAXA was established in 2004 after the integration of Tamura Electric Works, Ltd., and Taiko Electric Works, Ltd. It is a leading developer, manufacturer, and seller of network and security solution systems. The company provides a wide range of products such as business phone systems, card reader/writer systems, and home security systems.

Significant changes in design environment, such as higher heat generation rate in a faster CPU and the popularity of space-saving products, urged the company to introduce a thermo-fluid analysis tool. These changes made it difficult for design engineers to predict possible thermal issues only from their experiences or guesses. In the meantime, the company could no longer deal with shorter lead time by adding heat sinks or louvers onto prototypes, or by reworking product design. Mr. Suzuki says, "Here, SAXA decided to implement "theoretically well-supported thermal design, without reworking completed products."

In 2008, SAXA established "Thermo-fluid analysis working group" to introduce and radicate a thermal analysis tool. SAXA has several departments for product development: hardware development department for electronic/circuit design, mechanism development department for chassis design, and software development department, etc. Originally, the mechanism development department was in charge of all thermal issues, so the working group was started with four members of this department. Later, two more members joined the group from hardware development department as their cooperation and found imperative to solve thermal issues fundamentally.

Fig.1: Comparison of three different thermal analysis software results

Fig.1: Comparison of three different thermal analysis software results

Temperature variation is analyzed and compared to the measured values for a SAXA product.

Choice of Analysis Tool based on Accuracy and Usability

The working group selected a CFD (Computational Fluid Dynamics) tool based on the following two conditions: high accuracy/stability of the analysis, and the simplicity of the operation. Simplicity of the operation is crucial because design engineers had to perform analyses themselves in SAXA. As a first step, the working group asked three software vendors to analyze a SAXA product in order to compare the accuracy of the software product. When they compared the simulation results to the measured temperature at each point of the product, the results were as shown in the fig.1. Here, HeatDesigner showed extremely high accuracy with only 22°C temperature difference from the experimental results at maximum, which is far better than the results of company X with 126°C temperature difference at maximum. HeatDesigner also showed a higher operability than the tools of other companies'. Also, the analysis was successfully performed using regular mesh without adding any modifications to the original data in HeatDesigner. In contrast, frequent and time-consuming modifications were necessary during the mesh generation in the other tools. Furthermore, another deciding factor was the precise instructions and support from Software Cradle during the analysis. Finally, the working group selected HeatDesigner for the highest accuracy, simple operation, and rather low cost.

Environment to Take Full Advantage of the Analysis Tool

In many cases, CFD tool is not fully utilized by design engineers and not firmly established as necessity in a company. To prevent this from happening, SAXA facilitated the environment for steadily obtaining the benefits by setting operation rules and evaluation methods of analysis data.

Here, what the working group did was this. First, they created a procedure manual about thermal design and circulated it through the company. Then, they made a checklist for whether each product needs thermal analysis or not. Even if only one condition in the checklist applies to the product, an analysis is to be performed. Mr. Suzuki says, "We have developed rules to prevent design engineers from misjudging that a thermo-fluid analysis is not necessary for a product, which actually requires an analysis." Based on the checklist, most of their products usually become the target of analysis, he says.

Other important factor to be focused was a report format to record the analysis conditions which they made. In this format, items such as the type of components, their mounting surfaces, power consumption, size, and operating temperature limit are all listed. Types of components include CPU, RFID (Radio-Frequency Identification Tag), memory, regulator, and coil, etc. For the power consumption, values are recorded with distinction of measured, predicted, or the maximum. If the maximum value specified in the product catalog is used for the power consumption, the simulation results can be less reliable than the results obtained with the measured value. In this case, engineers can easily judge and decide to proceed to the next step even if the simulation does not show great results. Recording the precise analysis conditions like this substantially helps engineers objectively discuss the simulation results, also helping them avoid typical human errors such as input errors and misconceptions. Furthermore, the cooperation of hardware design department is indispensable to set these list items. This encourages discussion of engineers in different departments such as hardware development and mechanisms development.

They also created their original HeatDesigner operation manual and held study sessions about the operation. As a result, currently all twenty one engineers in the mechanisms development department can fully utilize and share the same simulation tool on a daily basis. They say most of them have learned the operation smoothly with the help of the operation manual. Such a situation in SAXA seems quite unusual and surprising for many other companies because generally only a few design engineers or dedicated analysis engineers utilize thermo-fluid analysis tools.

Koichi Hara, Mechanism development department, Manager, SAXA Development office

Koichi Hara, Mechanism development department, Manager, SAXA Development office

Thermal Analyses in the Early Stages of Designing

SAXA introduced HeatDesigner in September 2009. Careful preparations and great efforts by the working group enabled the smooth start-up. In SAXA, HeatDesigner is used in three phases: conceptual design, detailed design, and mass-production design. Koichi Hara, manager of mechanism development team in Development office, says "Analyses in the conceptual phase are very important."

In this phase, detailed hardware conditions are not specifically determined, yet the indicative shapes that can prevent thermal problems are predicted through analyzing rough dimensions and internal board layouts. Based on those shapes, design engineers of the hardware development team design circuit boards. In the detailed design phase, they create prototypes of new products after performing analyses with high accuracy by retrieving data for circuit and chassis design. Next, the final analyses are performed while creating molds for mass production. Then, they perform test productions and compare the test data to thermal to the simulation results. Here, if there is a gap between test and simulation results, they identify its cause and feed it back to the next analysis to accumulate the know-how and to improve the accuracy of analyses.

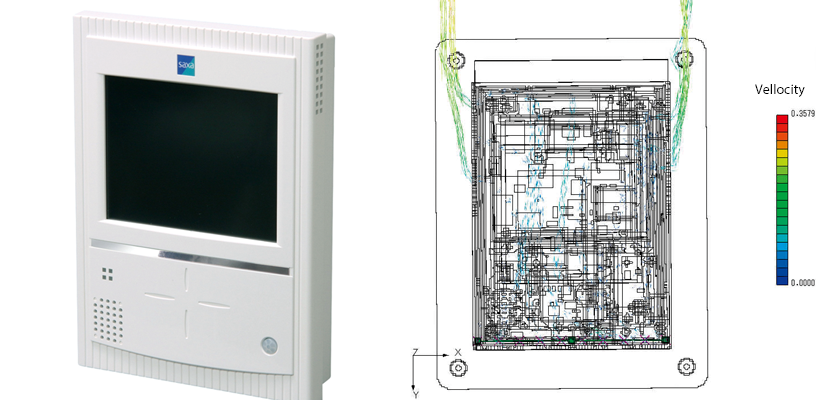

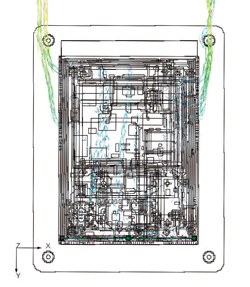

(Left) Fig.2: SAXA IC card reader "Card Terminal CT-600"

(Right) Fig.3: Thermal analysis for CT-600

Zero Production Rework after Test Production

HeatDesigner is providing various advantages in SAXA. Their greatest achievement is to be able to eliminate reworks after test productions. Mr. Suzuki says "Since analysis accuracy remains to be high as we expected, no thermal problem occurs after test productions". CFD analyses during the planning phase allow design engineers to find some obvious hardware errors and to fix those errors in advance, which is a big plus. Previously, they were not able to detect thermal problems before mass production. In most cases, they had to add some components such as adiabatic sheet, heat sink, or heat release sheet, also they had to pay extra cost for remodeling molds. Mr. Hara says "Not only the extra cost, but also the man-hours would increase considerably. Performing thermo-fluid analysis in the early phases can reduce these useless reworks or wasted costs."

Furthermore, the introduction of CFD tool stimulates corporations between different departments. Originally only mechanism development department had dealt with thermal problems; however, these problems are usually caused by many factors relating to other departments. Thermal analyses using the tool give logical explanations as to what causes high temperature and how it can be resolved most effectively. CFD tool gives them persuasive power and plays a role as the communication tool with the hardware design department.

Key Components: Active Efforts by the Working Group and Usability of the CFD Tool

The reason why the thermo-fluid analysis tool was firmly established as necessity in SAXA is that the working group successfully functioned as the organizer of the project. Since the group members always had to face thermal problems and recognized the importance of solving the problems, they seriously worked on the problems. As a result, they built a system to perform CFD analysis in the early product design phase and to introduce a report format for objectively analyzing simulation results.

In addition, "Sagamihara forum", in-house event of the company, must be one of the key factors for their success. In this event, all engineers in the technical departments can call attention to others, share their daily efforts and achievements. In this event, the working group announced their plan to perform CFD analyses. Soon after the announcement, they were able to show their successful case. Through their successful example, everyone in the company recognized that possible thermal problems can be solved in advance by performing simulations.

On the other hand, the tool having a high degree of usability played a part to make analyses take root in the company. People who have to perform analyses are mainly in charge of product design so that they usually cannot spare enough time to learn about thermo-fluid dynamics. Even under such circumstances, design engineers can utilize HeatDesigner with ease. Errors rarely occur while meshing or solver calculation, and this made engineers accept the tool very smoothly.

The working group is now trying to review the setting parameters to further improve the analysis accuracy. Also they are trying to apply the achievements in basic thermal analyses to more complicated analyses. In addition, the group is aiming to perform analyses with solar radiation or rain water for their in-car products or outdoor equipment. Now they are considering introducing the upper-range product of HeatDesigner "scSTREAM", from Software Cradle.

In this way, SAXA has accomplished their achievements in quite a short time by selecting the tool that is userfriendly and fits the on-site needs. The successful example of the company can be helpful for other companies considering countermeasures for thermal problems.

SAXA Inc.

- Established: February 2, 2004

- Business Fields: We will expand businesses through integration and create new core businesses, with Network Solutions and Security Solutions as core businesses

- Representative Director and President: Masao Koshikawa

- Headquarters: TOKYO

- Capital: ¥10,836,678,400 (as of March 31, 2011)

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of January 31, 2013 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download