OGK KABUTO Co.,Ltd.

Using CFD (Computational Fluid Dynamics) to Improve Aerodynamic Performance of Helmets for Sports and Motorcycle Racing Games at the Olympics

OGK KABUTO develops helmets for athlete cyclists and motorcycle drivers. They undertake CFD analyses in early phase of product development as well as wind tunnel experiments to simulate how inner geometry affects the performance. Having introduced the first aero components in this particular field using highly developed technology, OGK KABUTO aims for further improvement of aerodynamics and minimization of development phase.</strong

The businesses of OGK KABUTO consist of three main categories: development of helmets for motorcycle drivers, athlete cyclists, and children. Not only they hold the largest market share in Japan, they are also dominant helmet manufacturer in Asian market. OGK KABUTO became independent from OGK CO.,LTD, a major manufacturer of bicycle seats for children in 1982. Since then, they have been developing the helmets specially designed for motorcycles and bicycles. They are one of the few manufacturers that develop helmets for both motorcycle drivers and bicycle cyclists.

The strengths of their products are high aerodynamic performance and light weight, which were achieved through unusual development approach such as applying unique non-spherical geometry at the time where all other helmets were considered round. OGK KABUTO has been the official sponsor for Japanese national athlete teams for the Olympics and other sport championships, where their products are used by participants. As well as being recognized for the remarkable technology, they are also known for reliable credibility, which is proved by their products that meet safety standards of various countries across the globe.

Picture 1: Mr. Hiroshi Ota

Picture 1: Mr. Hiroshi Ota

Product Development Sec., R&D Dept., OGK KABUTO Co.,Ltd.

Products that Satisfied Severe Safety Standards

Mr. Hiroshi Ota (Picture 1) is in charge of product development and aerodynamic investigations needed for satisfying safety regulations in each country. Whether it is for motorcycles or bicycles, requirements for attaining safety standards and means of testing differ depending on countries. For example, the acquisition of Snell Standards, an US standard for applying a helmet shell (the outer layer) made of FRP (fiber reinforced plastics) is and one of the world’s most difficult specifications to attain. In order to acquire this specification, laminate configuration around FRP must be efficiently constructed. Another example is a quality test to evaluate product strength used in European regulations, which involves colliding helmet to rocks. To pass this test, they made sure that the product satisfies the required strength by conducting experiments of prototypes that were manufactured at real time, and changed the laminate configuration where necessary, which was then used to produce improved versions for further experiment examinations. OGK KABUTO conducts research on new materials and computational simulations.

One more factor to bear in mind is shapes of human heads, which differ depending on continents. Athletes in the Europe tend to have long and slim heads. This means that M sized helmets made for European athletes are too small for Japanese athletes, even if the size is doubled. Using the scanned database of various head geometries and the experience from the past development, OGK KABUTO develops highly capable helmets that meet design requirements.

Picture 2: Akiyoshi Kuchino, Manager, Planning and Public Relations Sec., R&D Dept., OGK KABUTO Co.,Ltd.

Picture 2: Akiyoshi Kuchino, Manager, Planning and Public Relations Sec., R&D Dept., OGK KABUTO Co.,Ltd.

Aerodynamic performance of helmets is equally important to consider. “Helmets could change the finishing time by several seconds, especially when used in triathlon and track races that involve long distance. Validating the aerodynamic performance of helmets is important for races, where a second loss could be fatal,” says Mr. Akiyoshi Kuchino (Picture 2) .

Wind tunnel experiments have played a significant role in development. Since before they introduced CFD tool, they have conducted wind tunnel experiments using mockup models and aerodynamic analyses. The experiments took place in the company facility in collaboration with Mr. Akira Azuma (Professor Emeritus of Tokyo University), Mr. Nagakatsu Kawahata (Professor, Nihon University) and Mr. Kunio Yasuda (Professor, Nihon University). Seeing how CFD was used to lower cost in vehicle industry, OGK KABUTO started considering its application.

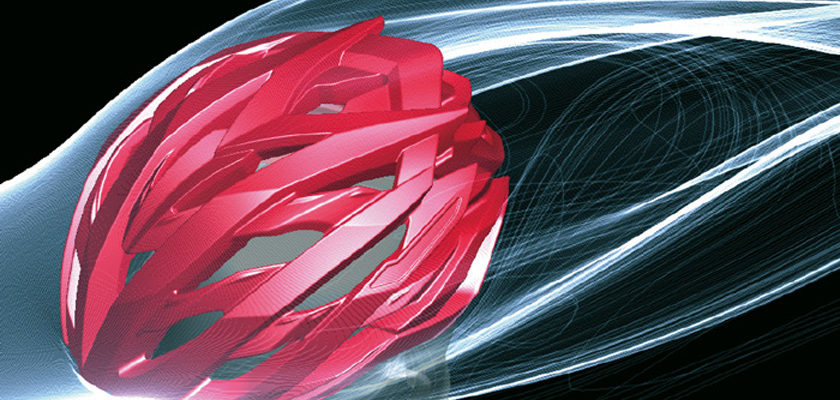

Fig 1: Analysis results of streamlines used for PR purpose. Visualized images are used to show strengths of the products effectively.

Fig 1: Analysis results of streamlines used for PR purpose. Visualized images are used to show strengths of the products effectively.

Analysis Images for PR Purposes

OGK KABUTO introduced SC/Tetra aiming to minimize development time, reduce cost, and visualize the air flow. Although tuft flow visualization was possible in wind tunnel experiments, details could not be identified. It was also difficult to evaluate the effect of changing the geometry by few millimeters. In addition, experiments were costly in terms of number of tasks. The initial prototype is first created by putty, which is used to create a wearable mockup; this will be then evaluated in wind tunnel experiments. The entire process must be repeated. “Mockups cannot be easily made. Some required several years to develop,” says Mr. Ota.

“Another benefit of SC/Tetra was that the analysis results can be used for PR purposes,” says Mr. Kucniho (Fig 1). As the company is well-known for products with high aerodynamic performance, OGK KABUTO considered that visualizing the air flow would be an effective means of conveying the product capability to their users.

OGK KABUTO says that the analysis results are effective visual materials for PR purposes. “Visual impacts are astonishing. We use SC/Tetra to generate images for PR purposes, as we can adjust the position and colors as to show beautiful details of mesh elements,” says Mr. Ota.

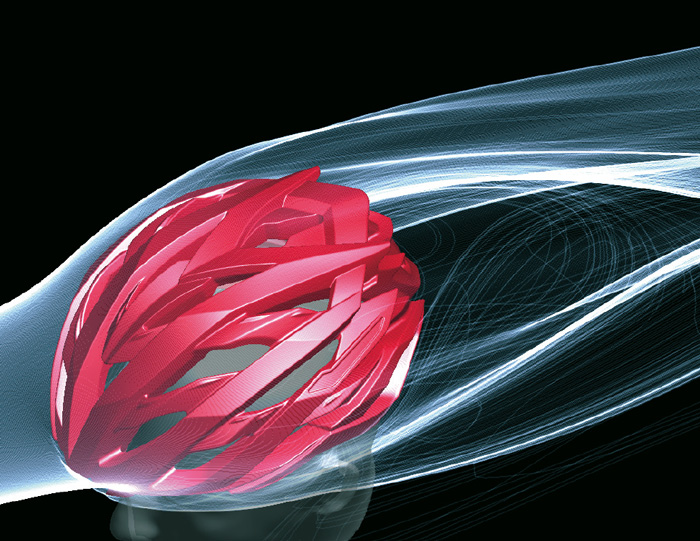

Picture 3: WG-1, a helmet for cycling sport

Picture 3: WG-1, a helmet for cycling sport

First Aero Components in the Industry that Control Turbulence

Analysis results (Fig 2) of WG-1 (Picture 3) for athlete cyclists indicate that the air flows through helmet interior.

Fig 2: Analysis model.

Fig 2: Analysis model.

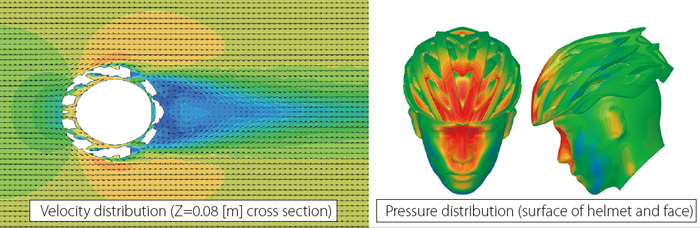

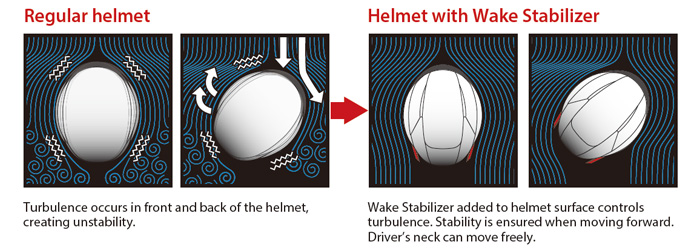

Fig 3: The effect of Wake Stabilizer

Fig 3: The effect of Wake Stabilizer

The device controls air flow around the helmet that occurs while driving (Patent no. 4311691)

OGK KABUTO developed Wake Stabilizer, the patent-registered aerodynamic device, in collaboration with universities. Fig 3 shows velocity distribution of RT-33, a motorcycle helmet, with and without Wake Stabilizer. Traditionally, the shape of a helmet was considered round, but researchers pointed out that “round objects are unstable. They will drift off the expected path.” Mr. Kuchino recalls: “just like a no-spin shoot in soccer, round objects with no rotations tend to stray off the motion pattern. The fact surprised us when we heard it for the first time." This led to the development of Wake Stabilizer, which made the helmet surface intentionally uneven. Round helmets are unstable as turbulence occurs at the back. Making the surface uneven means that the turbulence occurrence can be avoided and the entire head is stable when moving forward, allowing the neck to smoothly move without being interrupted by fast speed.

Picture 4: RT-33, a motorcycle helmet

Picture 4: RT-33, a motorcycle helmet

Mr. Kuchino, who actually wore the improved helmet and experienced the enhanced changes, says that it feels nothing like the previous model. Drivers may drive at the speed exceeding 300km/h in some motorsport races. Resistance can be clearly felt when trying to move their necks while driving at 100km/h or more. However, wearing Wake Stabilizer enables drivers to move their necks regardless of the speed. Their users including professional drivers confirmed that they could radically reduce the burden on neck when running through motorways.

“We have applied rectangular shape for our helmets long before it was first used for the back of vehicle body. Although it was seen as unconventional at that time, our competitors now use the same approach to develop products,” says Mr. Kuchino.

Experiment Results Conformed to Analysis Results

Mr. Ota says that the simulation and experiment results are “suprprisingly a close match. Results of wind tunnel experiments often fluctuate but that cannot be helped.” The fluctuations are due to difference in air density, which is determined by temperatures of the day. Analysis results could be affected by changes in voltage that makes the wind tunnel unstable and tilts of helmets that alters air flow slightly. Mr. Ota thinks that CFD simulations can be trusted when identifying the pattern of aerodynamic performance far more than experiments.

Upon introducing CFD software, OGK KABUTO looked at several tools as well as SC/Tetra. The reason why they chose SC/Tetra was because the tool was developed by a reliable Japanese firm. The fact that the tool is used by a lot of major international corporations helped them make decision. Trial seminars were also satisfying. “I felt that SC/Tetra was most operable out of others,” says Mr. Ota. Settings are simple for high-end CFD tool, and a lot of processes including mesh generation can be executed automatically. They were also happy with the diverse range of Postprocessor functions. Mr Kuchino says: “when we use analysis results for PR purposes, I give several requests to analysts to make sure that the images are simple enough for non-experts to understand, and they don’t disappoint me.”

One of the functions Mr. Ota values is wrapping, which is used before conducting fluid simulations of CAD models. During the development, models are often scanned using 3D scanner and converted to STL files. Whereas a considerable amount of STL file adjustment is needed in other tools, SC/Tetra wrapping function enables users to easily generate model data with enough accuracy for analyses, although geometries are slightly uneven. “We need to generate more accurate models with precise geometries for final analysis, but we use wrapping function to generate rough model for prior evaluations. When we want to see the effect of attaching parts with slightly different shapes, we can just wrap the scanned data and start analyzing right away,” says Mr. Ota.

CFD-oriented Development Approach First Used for Olympic Models

As the experiment and simulation results agreed with each other, OGK KABUTO found that they can undertake evaluations without actual models. They are eager to investigate the ventilation of helmet interior and air flow further. This cannot be identified in wind tunnel experiments. They expect that SC/Tetra will be useful for examining the details.

The current challenge of OGK KABUTO is the development of helmets for Rio 2016 Olympics. For this, they take CFD-oriented development approach for the first time. As an initial phase of development, they use geometry data to conduct simulations repeatedly. The model they are currently developing is planned to be used for the next season’s leading model. “If we become more proficient with SC/Tetra, the development speed will be much faster in few years’ time. The objective of the company as a whole is to reinforce our strengths, which are high aerodynamic performance and light weight,” says Mr. Kuchino.

SC/Tetra is expected to improve product development of OGK KABUTO dramatically.

OGK KABUTO Co.,Ltd.

- Founded: September 1982

- Products: Helmets and related products for motorcycles, bicycles (for children and adults), and sports

- Representative: Shuji Kimura, CEO

- No. of Employees: 87 (as of October 2014)

- Capital: 20 million JPY

- Location: Nagata, Higashiosaka-shi, Osaka (Japan)

- Website: http://www.ogkkabuto.co.jp/english/

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of June 1, 2015 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download