Nihon Automobile College (NATS)

Picture 1: Student Formula Japan 2013

CFD Tools Help NATS Team in the Student Formula Japan by Improving Vehicle Performance

NATS entered and placed seventh in just their fourth appearance in SFJ 2013, where participating teams compete on vehicle design, performance, mass production cost estimation, and presentation skills. A major technical improvement was the use of SC/Tetra to conduct fluid analysis that resulted in enhanced vehicle drivability and production of professional quality presentation materials.NATS was founded in 1989 to offer educational training and programs on automotive engineering. Their diverse programs include a two-year Mechanics course, three-year Customization course, three-year Motorsports course, and four-year Research course. Each course is practical, and highly focused. The Mechanics course provides lectures and hands-on, on-site training for students to become certified mechanics. In the Customization course, students learn about designing and manufacturing vehicles that meet mandatory legal and safety requirements. The Motorsports course teaches team management and the preparation needed to field a competitive entry in automotive racing. The Research course offers training for students to become First Class Auto Mechanics (the highest certificate for automotive mechanics in Japan), classes in 3D CAD design and manufacturing using CATIA V5 and ThinkDesign, and classes in management and marketing.

NATS is well known for its technical facilities. The college is equipped with a 1.2km race circuit, a 1.5km dirt track and maintenance rooms, allowing students the full advantage of experimenting in the field and enhancing their learning experience. NATS also offers opportunities for students to attend business expos and take a part in activities outside the college. NATS exhibited an Electronic Vehicle (EV) sports car at the 2013 Tokyo Motor Show 2013. This ultra-compact EV sports car won the Custom Car Grand-Prix at the Tokyo Auto Salon 2014, one of the largest competitive events for custom cars across the country.

About Student Formula Japan (SFJ)

NATS started using SC/Tetra CFD software in 2011 to analyze the performance of their SFJ vehicle (Picture 1). SFJ is a tournament where students compete on design, manufacturing and presentation of their compact racing car entries. The event encourages participating students to gain hands-on experience with vehicle design and manufacturing and to deepen their understanding of the automotive industry. Participants are judged by their vehicle design, performance, cost and mass production estimation, and individual presentation skills. The SFJ concept originated in the US and was later brought to Japan by the Society of Automotive Engineers of Japan. The Japanese version of this event has been held each year since 2003. SFJ’s success is apparent by the number of the participants. 4,738 students participated in 2013, coming from both domestic and international universities, colleges, and academies.

Picture 2: Cost report with 1,000+ pages

Picture 2: Cost report with 1,000+ pages

In most cases, participating teams spend a whole year preparing for this five-day competition. Teams score points by passing the standard inspections, static assessment and operational assessment. Static assessment involves reviewing three aspects of the vehicle production process: cost estimation, vehicle design, and presentation. To proceed to the next inspection step, each team must submit a cost report (Picture 2), which can be 1,000 pages long and over 10cm thick. The report must demonstrate that the team has considered fully burdened manufacturing and material costs and labor expenses. Design assessment focuses on design concepts, engineering technologies, design validity and the innovation. In the presentation assessment, students make a case to win the approval of referees acting as directors of a manufacturing firm.

Picture 3: Mr. Sho Murakami from the 3D CAD design manufacturing class in the Research course (on the left) and Mr. Hidenobu Hayashi, the Vice President of NATS

Picture 3: Mr. Sho Murakami from the 3D CAD design manufacturing class in the Research course (on the left) and Mr. Hidenobu Hayashi, the Vice President of NATS

Once the static assessment is completed, the operational assessment evaluates the actual vehicle performance and drivability, including acceleration, cornering, autocross and endurance. Vehicle endurance is assessed in a 22km race, where finish time, machine reliability and fuel efficiency are assessed.

Use of CFD Improves SFJ Outcome

NATS started using SC/Tetra CFD software in 2011 to analyze the performance of their SFJ vehicle (Picture 1). Mr. Hidenobu Hayashi (on the right, Picture 3), the Vice President of NATS, always felt that CFD analysis could improve the team performance in the static assessment phase. In his mind, the static assessment results were not at the same level as those for the operational assessment and final machine evaluation. NATS had already introduced structural analysis at that time and CFD was a natural progression. CFD analysis would enable students to improve vehicle capability by optimizing body and engine design and providing more persuasive visual evidence at the presentation assessment.

Challenging the Tournament with a Few Team Members

NATS students participated in SFJ 2013 with their vehicle, Formula Factory NATS-04 (FFN-04, shown in Picture 4), which was developed using SC/Tetra. The vehicle was 2,296mm long, 1,313mm tall, and weighed 260kg. It was capable of generating up to 54.5kW of power (when operating at 11,410rpm) and 46.4Nm of torque (when operating at 700rpm), from a 599cc engine.

Picture 4: Vehicle competed in SFJ 2013 (FFN-04)

Picture 4: Vehicle competed in SFJ 2013 (FFN-04)

The NATS team has steadily improved their placement in SFJ since their first year in 2010 when they finished 46th. They finished 21st in 2011 and 9th in 2012. They marked their best achievement in 2013 by finishing 7th. This was the highest position for all automobile technical colleges. A big reason for the team’s progress was attributed to improved vehicle designs, in particular, making the vehicle into a more aerodynamically sound shape.

“For the 2013 competition, we aimed to miniaturize the vehicle and minimize errors,” says Mr. Sho Murakami (on the left, Picture 3), a student from the 3D CAD design manufacturing class in the Research course. Mr. Murakami performed the fluid analysis of the actual model that competed the 2013 competition. He focused on simplifying the vehicle internal structure to reduce design variability and improve the probability of achieving the design target. Mr. Murakami was also determined to reduce vehicle weight which increased cornering efficiency, acceleration, engine rotation and fuel consumption. All of these affected the overall performance. Mr. Murakami calculated the weight of every component and by eliminating unnecessary parts was able to achieve substantial weight reduction.

For other reasons, Mr. Murakami’s team dramatically shrunk from 33 members in the previous year to 13 members. However, the smaller team met the schedule by standardizing parts and reusing components from the previous year’s vehicle. For example, they had previously used two different types of bell cranks for the front and back suspensions, but standardized them to keep the manufacturing efficient. Another problem was that the production process took longer than estimated. They had to repeatedly adjust the model and part allocation right up to the last minute before the contest. Their continuous effort and trials were rewarded by their seventh place finish at SFJ 2013. “It was hard to prepare with only a few team members, but it made the whole experience memorable,” concludes Mr. Hayashi with a smile.

Evaluating the Aerodynamic and Motion Performance Using SC/Tetra

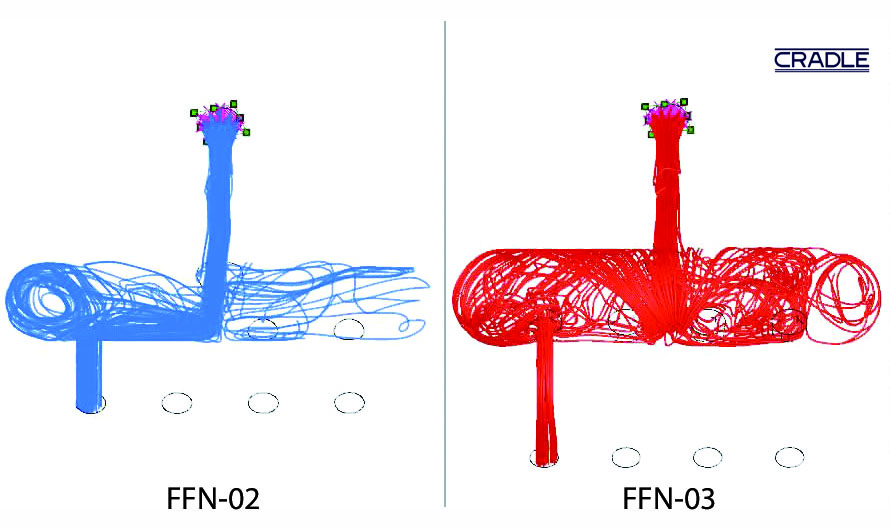

Mr. Murakami’s team used SC/Tetra to analyze the surge tank and aerodynamic performance of the vehicle. The surge tank stores and supplies air to each cylinder of the engine. They analyzed the previous vehicle model, FFN-02, which competed in SFJ 2011, and found that the inlet flow was non-uniform. After thorough evaluation, Mr. Murakami’s team enlarged the tank diameter from 70 to 90mm. Also, they changed the orientation of the intake manifold, which connects the surge tank to the engine, such that it was in line with the inlet and restrictor. Previously, the surge tank was at a right angle to the inlet and restrictor. As a result, the engine received a uniform inlet flow, as shown in Figure 1, and 2.8m/s higher maximum velocity.

Figure 1: Analysis of a surge tank

Figure 1: Analysis of a surge tank

Mr. Murakami explains that their team used CFD after the 2012 tournament to improve the aerodynamic performance of their vehicles, although they struggled to generate reliable results at the beginning. “We used to export CAD data in a format that can be read on a CFD tool and then surface-wrap the model before using it for the analysis. The trouble was that the original CAD data was not translated perfectly, ending up with gaps and layered faces which had to be manually repaired. Before SC/Tetra Version 10 was released, we had to simplify the original CAD data each time, but since Version 10 we can now accurately import the geometry CATIA files directly. This was a great improvement compared to before,” says Mr. Murakami.

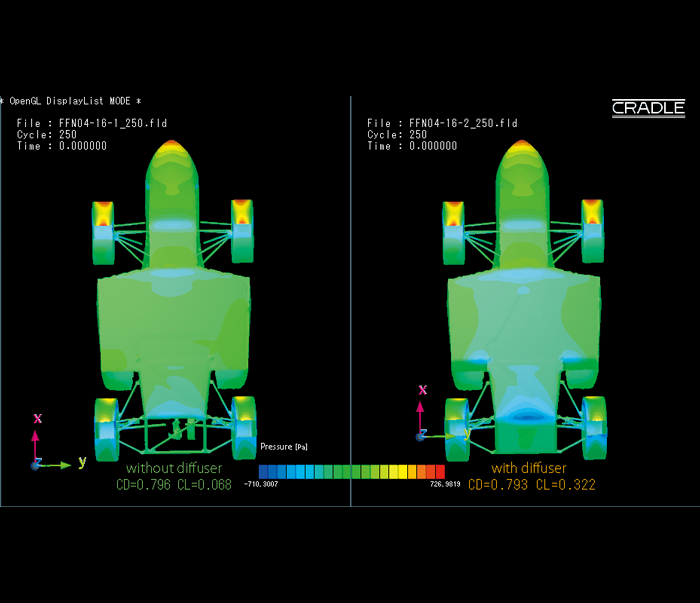

Aerodynamic analysis proved to be effective. For example, when Mr. Murakami’s team designed the vehicle’s underbody diffuser shape, they designed the diffuser to increase the down force by letting the air under the car to accelerate and reduce the pressure (Figure 2). They also achieved a reduction in turbulence by raising the shape of the side pod and minimizing the air blowing against the wheels.

Figure 2: Comparison of vehicles with and without a diffuser

Figure 2: Comparison of vehicles with and without a diffuser

Tutorials Providing Increased Expertise in Software Operation

One of the benefits of using SC/Tetra is its user-friendliness. Mr. Murakami recalls that he “received a lot of help from the tutorials.” After Mr. Hayashi’s training for using the software and reading the tutorials, Mr. Murakami became comfortable using the functions in the software. “Our objective was to estimate CD*1 and CL*2 values so I looked at the tutorials with similar objectives and made calculations according to these examples,” says Mr. Murakami. The user interface was also easy to comprehend, especially for modeling and generating the mesh. According to Mr. Murakami, the tutorials “clearly indicated user actions needed for the next step.” He says that he could solve most of the problems on his own, by simply reading the Help sections and applying the suggested solutions.

Mr. Hayashi says that he was satisfied with Cradle’s prompt technical support for the inquiries he made about the manifold analysis. Mr. Murakami further notes that performing CFD analysis enabled him to visualize phenomena that cannot be easily observed in experiments. “I was fascinated to visually learn that even a slight change to the cowl dramatically affected the flow,” says Mr. Murakami. His interest in fluid dynamics has increased considerably since he started using CFD.

*1 Abbreviation for Coefficient of Drag

*2 Abbreviation for Coefficient of Lift

Using SC/Tetra for More Accurate Analysis

Although Mr. Murakami’s team has primarily used CFD to visualize the effects of changes to models, they are planning to set numerical goals and use the analysis to determine the best design that meets the goal. They are also expecting to undertake investigations combining CFD analysis with other tools, including the Chassis Dynamometer that measures vehicle performance and power output. “As we begin to do this, we would love to consult the Cradle technical staff about how to model this system,” says Mr. Hayashi with anticipation.

The NATS campus is furnished with a 1/24 scale wind tunnel. Producing a prototype can be done much more easily today than years ago with the advent of such tools as 3D printers. NATS 3D printing offers many opportunities for building accurate physical models quickly. NATS also believes that modeling of the cowl can be further improved by combining wind tunnel experiments with CFD analysis.

To summarize, NATS is an excellent case example where applying SC/Tetra has helped them achieve a better learning environment and tournament results. The software is expected to provide extensive and sustainable support for future students.

Nihon Automobile College (NATS)

- Established: 1989

- Founder: Nichiei Academy (educational foundation)

- Type of school: Technical college

- Location: Narita-shi, Chiba, Japan

- Courses provided: Mechanics, Customization, Motorsports, and Research

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of January 31, 2014 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download