Aomori Prefectural Industrial Technology Research Center

- Thermal Analysis is Beneficial for the Design of Food Contaminant Scanners

- Usability was a Deciding Factor in Choosing HeatDesigner for the Analysis Tool

The Hachinohe Industrial Institute is one of the affiliated laboratories of the Aomori Prefectural Industrial Technology Research Center (hereafter the Research Center). A Prefecture is an administrative district. Japan consists of 47 prefectures. The Research Center uses HeatDesigner to help solve thermal problems for electronics. The range of applications includes scanners for food contaminants, devices for measuring the quantity of sugar and moisture in agricultural products, and inspection devices for assessing moisture and heat in coal and biomass.

Picture 1: Mr. Toru Okayama (D.Eng), Chief Researcher, Machine System Division, Administrative Manager, Hachinohe Industrial Institute, Aomori Prefectural Industrial Technology Research Center

The Research Center spun off from the prefectural administration and was reorganized as an independent organization in 2009 with the intention of promoting local industries and economic development in Aomori. “Our strength is that we have cultivated a wide variety of technologies through research and development, which includes manufacturing, agricultural, marine, and food processing products,” says Mr. Toru Okayama (Picture 1). Intending to build and sustain collaboration and close relationships with local businesses, the Research Center conducts research and development for new products and technologies, investigations of natural resources, and development of agricultural and pest control technologies. They also provide technical consultation, test services, and training to the local companies.

The Research Center consists of 13 laboratories dedicated to the growth of industries and community partnerships. Some of the laboratories work on topics related to forestry, livestock, and vegetation. Other laboratories focus on developments in manufacturing. These include the General Manufacturing Institute, the Hirosaki Industrial Institute and the Hachinohe Industrial Institute. Mr. Okayama works for the latter. The General Manufacturing Institute works with environment and energy development. The Hirosaki Industrial Institute focuses on biotechnology and production design. The Hachinohe Industrial Institute works with materials machineries, and production process improvement.

Mr. Okayama is involved in collaborative research and development projects that come from inquiries and experiment requests from local enterprises. His research ranges from material science to device design. The Hachinohe Industrial Institute uses HeatDesigner, a thermal fluid analysis tool specially developed for electronics.

Thermally Sensitive Food Contaminant Inspection Devices

One of the reasons the Hachinohe Industrial Institute started using HeatDesigner was for the development of an inspection device for food contaminants. In this case the contaminant was hair. Thermal design is crucial due to the thermally sensitive characteristics of the device. It identifies hair by inspecting the near-infrared absorbance of cystine, one of the constituents of hair. The device irradiates near-infrared rays at the target, collects the reflected signature, and analyzes the spectrum using a spectroscope. Using the institute’s algorithm, the device determines whether the detected signature conforms to conditions where hair is either present or absent.

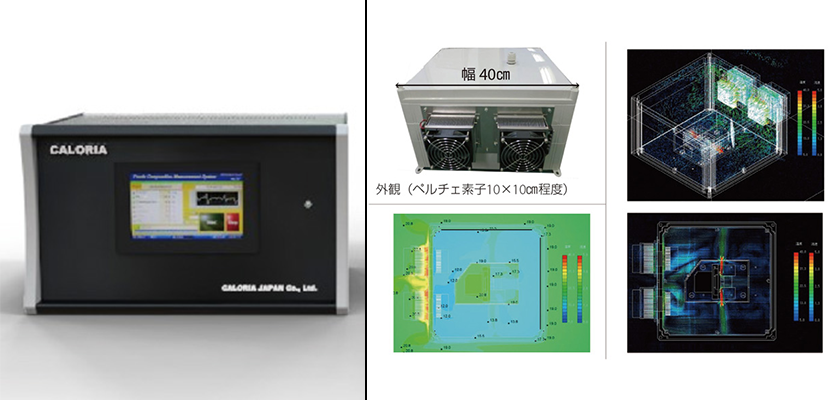

The Research Center develops the inspection device in collaboration with Caloria Japan Co.,Ltd., a local enterprise in Aomori. During development, the engineers observed that the reflected signature fluctuated depending on the time of day (Fig 1). In particular, the signature changed between the morning and afternoon. This caused the engineering team to explore the value of using thermal simulations to help them better understand system and environmental effects.

During development of the inspection device, the device was normally subject to stable laboratory conditions. However, the device developed by Mr. Okayama is designed to be used anywhere in the production line. In these conditions a number of factors can affect inspection performance. These include temperature, humidity, and fine particles in the air. “In reality, the device could be used in a situation we never expected. There is no problem if it is in a controlled environment, but it isn’t in many cases,” says Mr. Okayama.

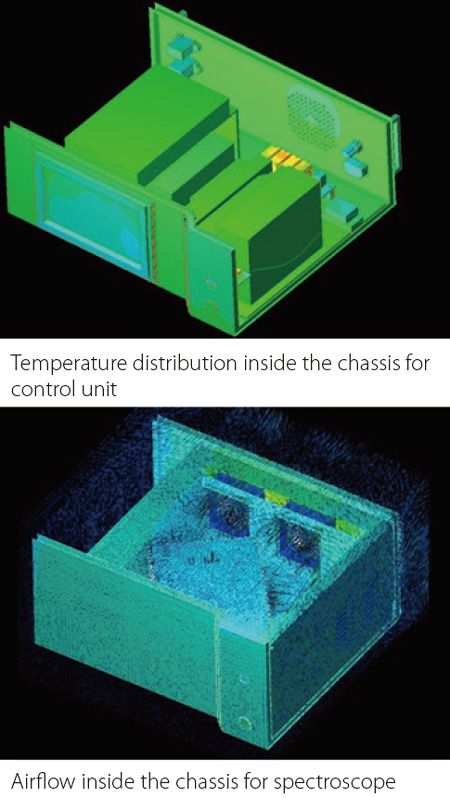

Fig 1: Controlling the temperature inside, spectroscope (the actual temperature shows that the inside temperature is kept at the same level)

Fig 1: Controlling the temperature inside, spectroscope (the actual temperature shows that the inside temperature is kept at the same level)

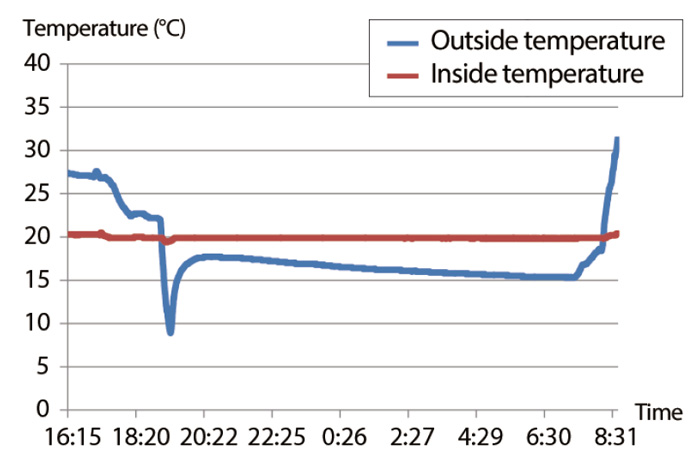

Fig 2: Spectroscope for hair inspection unit (temperature contour on lower left, distribution of inner velocity on right).

Fig 2: Spectroscope for hair inspection unit (temperature contour on lower left, distribution of inner velocity on right).

After conducting CAE analyses, the Research Center implemented a sealed chassis for blocking dust and fluids. In addition, a Peltier device was used to lower the temperature (Fig 2). In search of the ideal combination, the engineering team studied the output of Peltier device, the surrounding environment, fan flow rate, and the fan position. They decided to attach fans inside and outside the device and to locate the Peltier device between them as shown in Picture 2.

Food contamination by insects has become an interesting topic in Japan, and the food industry is paying more attention to inspection techniques. Commonly known food inspection devices such as metal inspectors and X-ray machines are not capable of identifying insects and other living creatures. Mr. Okayama hopes to be able to inspect for insects, plastics, stones and other contaminants in the future by using variants of the inspection device currently being developed.

Picture 2: Inside of spectroscope of hair inspection unit.

Picture 2: Inside of spectroscope of hair inspection unit.

Picture 3: Moisture meter for the sugar levels of potatoes.

Picture 3: Moisture meter for the sugar levels of potatoes.

Diverse Applications Possible Using Near-infrared Rays

Food contaminant inspection techniques can be used to measure other qualities. One example is using the measuring device to evaluate the level of sugar, moisture, and starch in potatoes (Picture 3). The sugar level in sweet potatoes can be measured while raw. The food industry has high expectations for developing the inspection device to measure other qualities in agricultural products and fruits.

Inspection devices to evaluate moisture and heat in biomass are also in demand. Through thermal compression, remains of apples, rice or chaffs, and other agricultural products can be converted to biomass fuels called bio-cokes. Companies making bio-cokes want to estimate moisture and heat of the target materials before conversion.

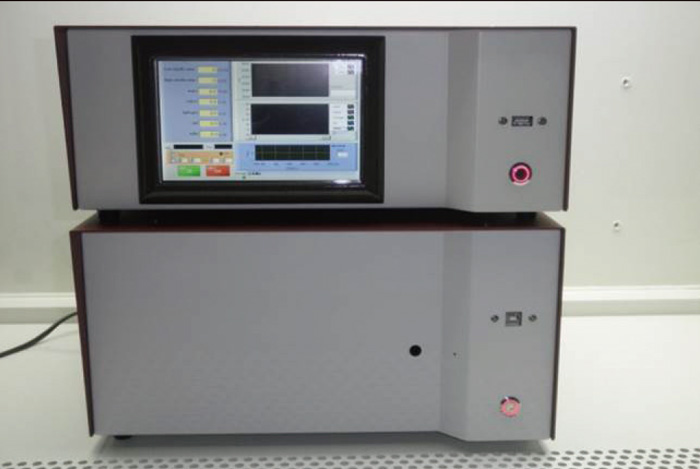

Picture 4: Heat generation of wood pellet and moisture inspection device

Control unit (above) and chassis for spectroscope (below)

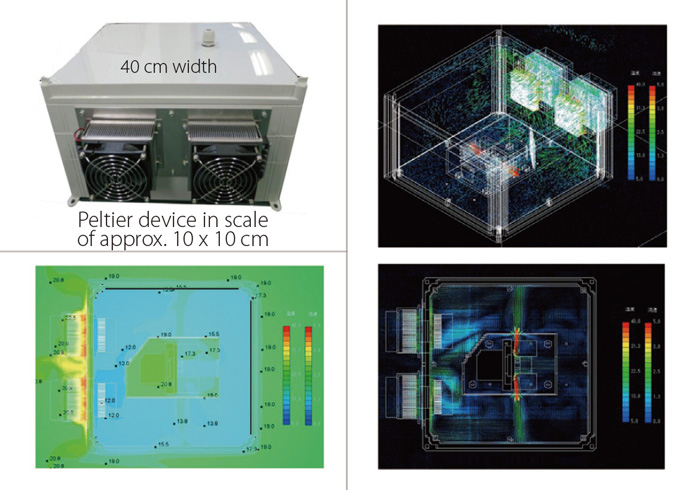

Fig 3: Heat generation of wood pellet and moisture inspection device.

Fig 3: Heat generation of wood pellet and moisture inspection device.

Mr. Okayama reveals that a prototype device has been made that measures heat generation and moisture levels in wooden pellets (Fig 3, Picture 4). To achieve further device miniaturization, the Research Center conducted analyses before determining the component layout for the spectroscope control unit and chassis. They studied the materials and heat generation of each component, and performed thermal analyses using thermal fluid analysis software to evaluate the temperature distribution inside the device. The results for the control unit showed considerable heat generation from the control relay. Mounting a fan close to the relay circuit effectively dispersed the heat.

By using a Peltier device to lower the temperature, the chassis for the spectroscope can be maintained at 23 °C. The fan attached to the spectroscope ensures sufficient ventilation within the chassis, which effectively suppresses the variation in the temperature distribution.

Component Management of Sewage Sludge

Mr. Okayama says that there is a demand to use the inspection device for managing sewage sludge processing. Sludge is dried and incinerated in a sewage plant, but the amount of moisture in the sludge is different depending on the season and location. The device could be used to measure the amount of moisture in real time, to determine the optimal drying method, and to control the components within the sludge.

Mr. Okayama reveals that an inspection device for heat generation and moisture content in coal is in the process of being verified. The device can be used in a research where coal is ground into powder, mixed with biomass, and combusted. It must survive a very hot environment, especially during the summer, and Mr. Okayama is working on developing a durable device that will function properly under such severe conditions.

As one of the priority businesses, the Research Center participates in food contaminant inspections and quality checks for garlic, which is an Aomori specialty. This work is done in collaboration with local enterprises. Calorie Answer, an inspection tool now available in the marketplace, was developed with the cooperation of the Research Center. The number of calories of a food product can be estimated by placing the product inside this tool which resembles a microwave. Similar to the hair inspection device, this tool also uses near-infrared rays and spectroscopy. Calorie Answer is capable of calculating the amount of calories (as generated heat) by radiating near-infrared rays to food samples and evaluating the absorption wavelength.

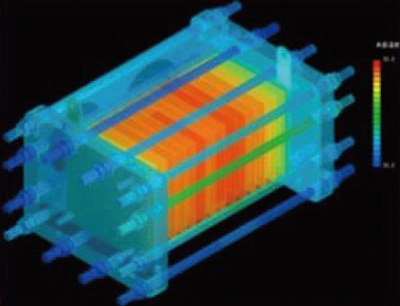

Fig 4: Small portable fuel cells

The Research Center is also developing small portable fuel cells (Fig 4). The output from fuel cells is determined by the number of cells. The existing design consists of 15 to 20 cells, each covered with an electrolyte membrane. The membrane deteriorates at high temperatures. Methods for heat dissipation can be implemented, or the number of cells reduced, to solve the problem. Verifying all these methods in experiments may be ideal; however, prior evaluations with thermal analyses can lead to even better methods for solving the problem.

Deciding Factors: High Operability and Approachability

Mr. Okayama first used HeatDesigner starting roughly in 2003, to conduct thermal analyses of liquid crystal displays and LED backlights. Mr. Okayama recalls that the reason for choosing HeatDesigner was “definitely its high operability.” The automatic mesh generation function also caught his attention. “We could not afford to just focus on thermal analyses, so we needed a thermal analysis tool even non-specialists could easily use,” says Mr. Okayama. As the Research Center staff is often reorganized, some of the staff is often using the analysis tool for the first time. Mr. Okayama needed an approachable analysis tool, which can attract the interest of non-experts.

Another feature Mr. Okayama thought necessary when choosing the analysis tool was the ability to show the analysis results in animations. “As we often collaborate with local enterprises, we need to demonstrate the effectiveness of our projects to third parties, such as academic circles and local administrations. We were looking for a tool that would enable us to visually show the effect in a simple manner,” says Mr. Okayama. HeatDesigner satisfied their requirements. Many of the collaborative partners had no prior experience using the thermal analysis tools. They welcomed the new tool with great anticipation.

Back in 2003, thermal calculations using other tools could take the whole night. Mr. Okayama used to start calculations before leaving the office in the evening and see the analysis results the next morning. He had hoped computation time would reduce when computer processing capability improved. Indeed, both improvements in hardware and software have now reduced calculation times to as low as 30 minutes in some cases.

Mr. Okayama undertakes CFD simulations and experiments simultaneously. “It was risky to produce a spectroscope without prior evaluation. Simulations helped us change the position of the fans and easily estimate their effects easily,” says Mr. Okayama. However, he always verifies the effects with experiments after running the simulations. For example, he verifies the temperature inside the spectroscope using a thermometer. He says that the internal flows cannot be detected in the experiments but can be visualized in the simulations.

Always Aware of Analysis Objectives

Throughout the projects, Mr. Okayama is always aware of the analysis objectives. If flow circulation needs to be improved, a close look at the velocity vectors may be required, but the pressure is not important. He explains that it is important to understand the purpose of the analyses and examine how the numerical analysis should be conducted.

Mr. Okayama is satisfied with the support provided by Software Cradle. “I get in touch with the sales engineer when I have a question. The responses and advice are extremely helpful,” says Mr. Okayama. Software Cradle sales engineers can accurately respond to inquiries because they are aware of how each user is applying the tool, the usage history and the installment background.

Mr. Okayama hopes to use thermal analysis more. For example, he wants to simulate the heat generated from a dry cutting manufacturing process. He also wants to simulate the temperature rise in a solar panel. He suggests that the uses of thermal analysis can extend beyond current applications. These include analyzing the melting of snow, predicting changes in sea temperature, and evaluating the effects of geothermal power generation. These are all related to the various industries in the Aomori prefecture. The strength of the Research Center is both their role as the center of the laboratory network and as the collaboration catalyst across different fields of research. The thermal fluid analysis tool is expected to be used in diverse applications.

Aomori Prefectural Industrial Technology Research Center

- Businesses: Promoting local industries in the Aomori prefecture including;

- Cultivating new technologies and crops and vegetation research, Investigating natural resources and the environment, Developing, researching, and consulting for pest control technologies, Providing training and seminars, and Arranging applications of industrial subsidies

- Main area: Manufacturing, agriculture, marine products, food processing

- Location: Kuroishi-shi, Aomori, Japan

- Website: http://www.aomori-itc.or.jp/

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of November 31, 2014 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download