Morinaga Milk Industry Co., Ltd.

CFD Application for Dairy Products: Scientific Exploration for Great Tastes

Morinaga Milk Industry develops and manufactures dairy and non-dairy food products. Their broad product range includes milk, cheese, dairy beverages, yogurt, ice cream, infant formula, and much more. They also produce functional ingredients such as Lactoferrin and Bidobacterium longum. The corporate motto is to serve as “your partner for great taste.” To fulfill their commitment, Morinaga Milk has pursued technological advancement to help them produce high-quality, healthy, and reliable products.

Image: Morinaga Milk products

To boost production efficiency and ensure food hygiene, Morinaga Milk conducts their own equipment and facility research and development. The Engineering Research Laboratory is one of the Morinaga Milk research institutes and is responsible for equipment design and development.

Development of new products often requires new equipment. The equipment is designed and manufactured by Morinaga Milk, although sometimes in collaboration with affiliated institutes. After the new equipment is thoroughly inspected, it is incorporated into production. Morinaga Milk conducts a wide range of research, such as food engineering, manufacturing process technology, and production technology. The outcome of their research has included new equipment such as manufactured aseptic valves, automatic inspection equipment and much more. One of their products, Purestar, which produces slightly acidic electrolyzed water, is highly recognized in the industry. It uses the characteristics of low-concentration chlorine water to improve the manufacturing process. The device won the Technology Award of the Japan Society for Food Engineering Awards.

Tetsuo Miyamoto, Dr. Eng., Senior Research Scientist, Engineering Research Laboratory

Hygiene and sterilization are critical factors that determine the quality of food production. Different measures of hygiene and condition grades are used for each product. For one product, hygiene might be promoted by refrigerating the item for two weeks; another product may require preservation at room temperature for three months.

Production process knowledge also varies depending on the types of products. For example, a certain drying technique is needed for powder food product manufacturing. Yogurt production requires fermentation skills. Ice cream production involves freezing techniques. Developments of equipment for these processes can involve analyses using computational fluid dynamics (CFD). Mr. Tetsuo Miyamoto, Senior Research Scientist of the Engineering Research Laboratory at Morinaga Milk, reveals that the company has switched to CFD oriented development in recent years compared to the knowledge-based, staff-dependent practices and textbook approaches used previously.

Applying CFD for High Quality Cream Products

Morinaga Milk has been using SC/Tetra since 2008. Mr. Miyamoto started using it since 2010. This began when their engineers recognized the potential of using computational analysis to help improve product quality. Until then, equipment upgrades were based on accumulated experience, knowledge, and experimental results. To further enhance equipment performance, the company decided to start using mathematical evaluations to help them to identify more efficient production methods. Their first application was performance validation of the cooling storage tank for fresh cream.

Cream is an oil-in-water (O/W) emulsion consisting of dairy fat extracted from whole milk by centrifugal separation. When mixed with sugar and flavorings, it forms whipped cream that is used for pastries and cakes. Applying more stress to the whipped cream leads to a phase transition, which transforms it into a water-in-oil (W/O) emulsion more commonly known as butter. Because of this unstable characteristic, it is crucial to minimize stresses in cream production.

This is especially important in the cream's final cooling storage process, which determines the quality of the cream. The ‘aging’ process for cream is designed to encourage recrystallization of fat globules and to stabilize the fat globule membrane. The increased viscosity of fat globules, due to agglomeration, leads to deterioration of cream quality. Milk fat globules tend to agglomerate more when stirred longer, when greater force is applied, or when preserved at higher temperature (5 to 15ºC). To produce high quality cream, the production facility must maintain a uniformly cold tank which generates instant cooling effects, and minimizes stresses to the cream.

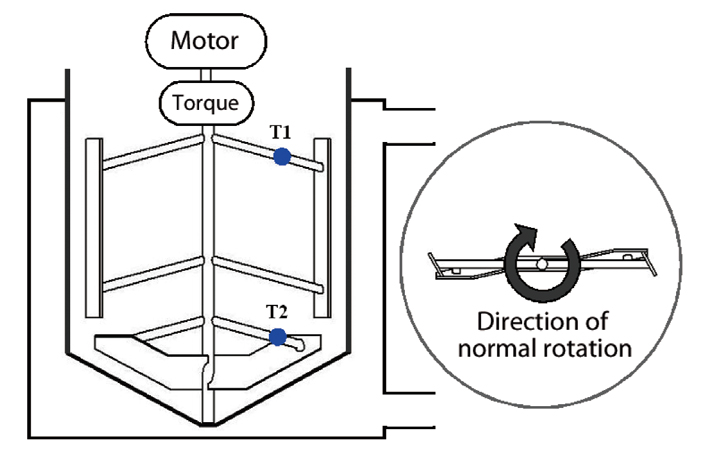

Figure 1: Schematic diagram of experimental equipment (Impeller 1).

Revalidation of the Stirring Tank using Experimental and CFD Results

As illustrated in Figure 1, a cooling jacket is wrapped around the cone-shaped experimental tank with anchor impeller. The baffle plates are not attached. Morinaga Milk production lines had used the same impeller geometry for many years. This geometry had been thought to minimize stresses to the cream and was also easy to clean. The impeller geometry and operational conditions had not been revalidated until now. The challenge when making cream is to achieve fast cool-down and gentle stirring. To eliminate the stresses to the cream and maintain the homogeneity of the tank environment, Morinaga Milk decided to re-evaluate the impeller geometry.

Morinaga Milk engineers first produced a one tenth scale experimental model of the existing 5m3 tank. Having conducted a number of tests to improve the impeller and determine the rotating direction, they used SC/Tetra to analyze the experimental model. The computer model contained 5.5 million mesh elements. Steady-state analyses were used to calculate the flow, and transient analyses were used to calculate the temperature.

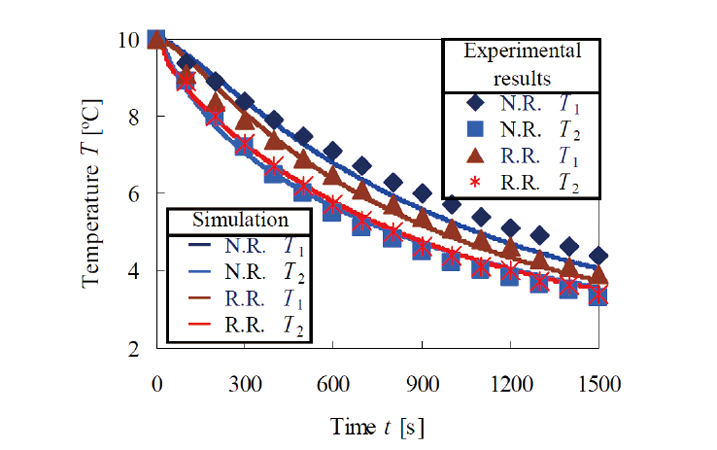

Figure 2: Comparison of rotational directions for Impeller 1 (Plot: Experimental result, Line: CFD result, Normal rotation: N.R., Reverse rotation: R.R.).

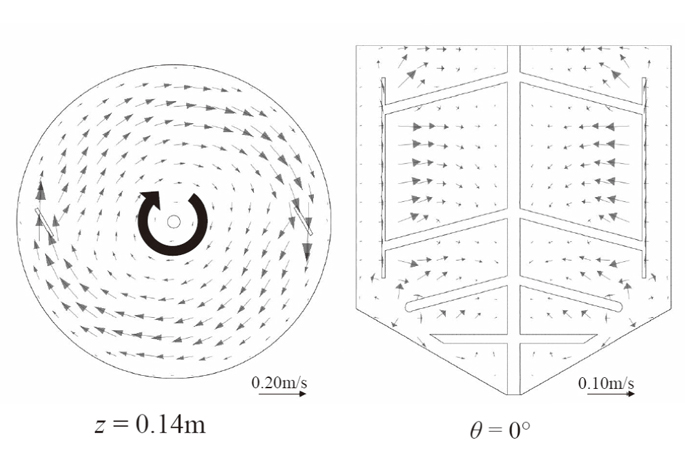

Figure 3: Velocity vector distributions of r-θ plane and r-z plane (Impeller 1 Normal rotation)

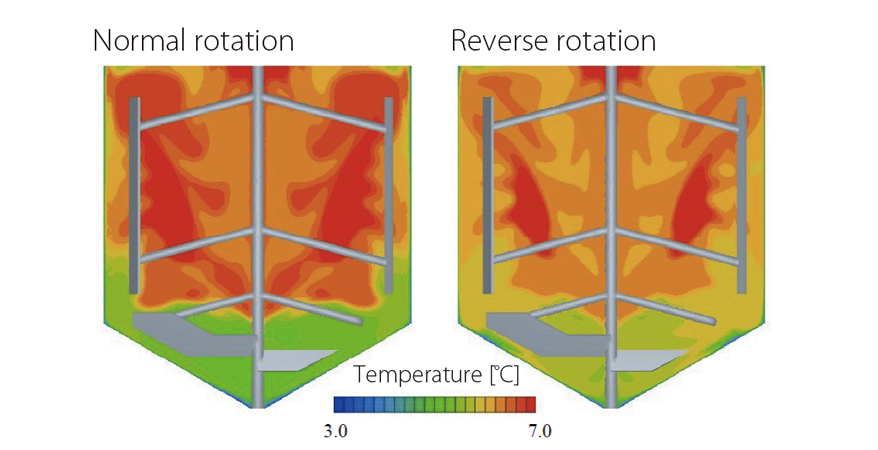

Figure 4: Temperature distributions of r-z planes (Impeller 1, θ = 0º, t = 600s).

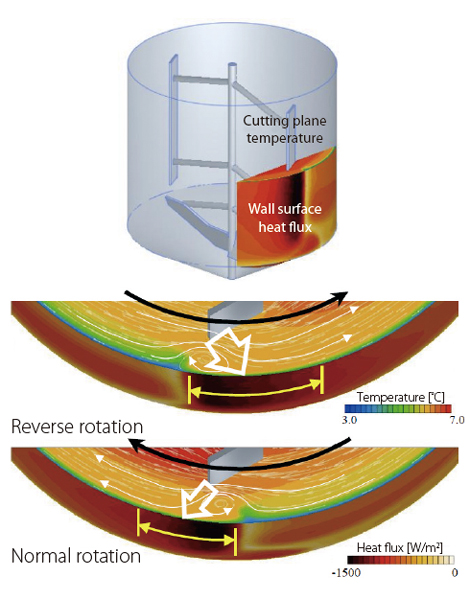

Figure 5: Heat flux distributions of the wall surfaces and temperature distributions of r-θ planes (Impeller 1, z = 0.14m, t = 600s).

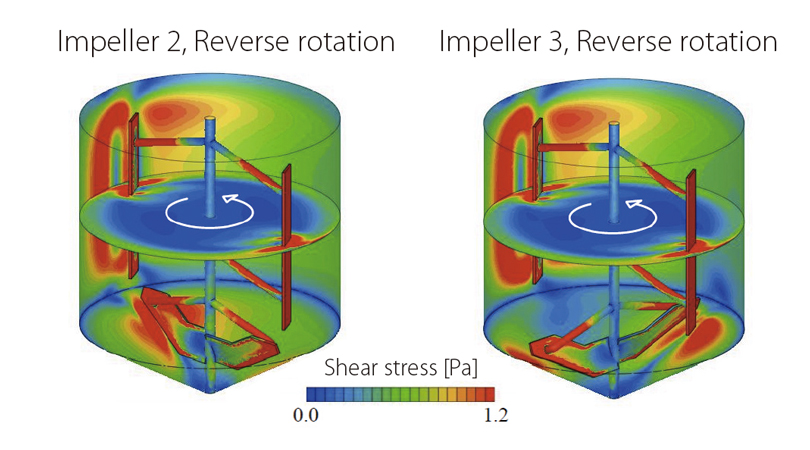

Figure 6: Shear stress distributions of the wall surfaces and r-θ planes (Impeller 2 and Impeller 3)

The analysis variables consisted of three different types of impellers: Impeller 1 consisted of the upper blade that rotated in the direction of the scraping force acting towards the wall. The lower blade rotated in the direction of the scraping force acting towards the bottom surface. Impeller 2 uses the lower blade with the attachment angle reversed. Impeller 3 offsets the phases of the upper and lower blades by 90º. Considering the effects of both normal and reverse rotations, Morinaga Milk calculated six patterns and compared them.

As shown in Figure 2, the experimental and simulation results for Impeller 1 agree well. Morinaga Milk engineers determined that the heat flux was magnified by the flow towards the wall generated at the upper blade with the reverse rotation. They also found that the homogeneity of the fluid was improved by the downward flow generated around the lower part of the upper blade and by the upward flow from the edge of the lower blade. Something else they learned was that they could minimize shear stress and shaft power by deliberately creating a phase difference between the upper and lower blades (Figures 3-6). Morinaga Milk applied this theory to a larger operating tank and successfully enhanced tank performance, production efficiency and product quality.

The Usefulness of Result Visualization

Upon completing the analyses, Morinaga Milk found that the laminar flow simulation results matched the experimental results more closely than anticipated. Visualizing the results helped explain the phenomena. For example, the scraping effect of a larger-sized impeller was smaller than predicted, and the flow fluctuated significantly. Visualization also helped the engineers explain their findings to the larger team.

Finding a Solution for Efficient Mixing and Sterilization

Now Morinaga Milk uses CFD to analyze other tanks. One of these evaluations focuses on operational speed and energy efficiency, in which they are looking at the characteristics of the mixed substance and mixing efficiency.

They are also using CFD analyses to simulate the airflow around food as it is being transferred to packages. This includes looking at the flow of hot air used to sterilize the inside surfaces of packages. The hot air, above 200ºC, was thought to immediately increase the temperature of the packaging. However, the analysis results show that the packaging temperature actually decreases, as the hot air ingests cold air from the surroundings. Visualizing the analysis results helps the Morinaga Milk engineers improve their understanding of the physical phenomena and innovate improvements.

Effective Post-processor Visualization

When SC/Tetra was first introduced, Morinaga Milk engineers struggled more with using 3D CAD to create the analysis models than they did actually using the analysis tool. Working in 3D was completely different compared to the 2D machine layouts they were used to working with.

Morinaga Milk engineers are eager to continue learning about additional capabilities in SC/Tetra that they can use for new analyses. They are happy with the technical support being provided. They are also amazed at the post-processor visualization capabilities in SC/Tetra, which has improved with every version upgrade. “I like the streaming arrows and other post-processor functions in SC/Tetra. They are visually clear and nicely illustrated,” says Mr. Miyamoto.

Challenge for More Complicated Analyses

Morinaga Milk is eager to tackle new challenges using CFD. They consider analyzing yogurt mixed with fruits, and ice cream mixed with nuts and sauces. Dispersion of air bubbles and crystal growth occur simultaneously during the manufacturing processes for these products. Although this is a highly complicated phenomenon to analyze, Morinaga Milk engineers believe that CFD will enable them to mathematically explore how manufacturing processes can be modified to improve taste and quality of these dairy products. “The analyses we are trying to undertake will be complicated. These will involve three-phase multiphase flow. But we are counting on SC/Tetra capability for generating accurate results,” says Mr. Miyamoto.

These CFD applications at Morinaga Milk demonstrate their analytical pursuit of greater taste. SC/Tetra has played a significant role, and it is expected to continue to advance product development at Morinaga Milk.

Morinaga Milk Industry Co., Ltd.

- Founded: 1917 (as Nippon Rennyu Co., Ltd.)

- Reorganized: 1949 (as Morinaga Milk Industry Co., Ltd.)

- Businesses: Production and sales of milk and other dairy and non-dairy food products

- Representatives: Akira Ohno (Chairman), Michio Miyahara (President)

- Location: Minato-ku, Tokyo, Japan (Head Office)

- Capital: Approx. 21 billion JPY (as of March 31, 2014)

- URL: http://www.morinagamilk.co.jp/english/

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of November 31, 2014 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download