WindStyle Corporation

Cradle scSTREAM Widely Used in the Architectural Industry

WindStyle (Niigata, Japan) is an engineering consulting firm specializing in wind engineering: the study of air flow around buildings. WindStyle uses Cradle scSTREAM Computational Fluid Dynamics (CFD) software to simulate the aerodynamics through and around a complex array of buildings. Compared to conventional wind tunnel experiments, CFD produces faster results and enables engineers to graphically visualize air movement. In an interview with Cradle, Mr. Tetsuo Matsuyama, the President and CEO of WindStyle, explained how CFD is used to study and solve a variety of wind engineering problems.

Tetsuo Matsuyama, President and CEO, WindStyle Corporation

Tetsuo Matsuyama, President and CEO, WindStyle Corporation

Mr. Matsuyama formerly worked at Kumagai Gumi before starting WindStyle in 2003. WindStyle has grown rapidly, and the company has undertaken nearly three hundred projects over this time period. Engineers at WindStyle perform CFD simulations using scSTREAM and also conduct wind tunnel experiments to validate solutions before making recommendations to their customers.

Many of WindStyle's projects involve evaluating wind flow around high-rise buildings prior to and during construction. The evaluations focus on predicting wind hazards, i.e. assessing how strong wind gust can blow things down, potentially even people, under the most severe conditions. While building codes do not require these assessments, building owners often consult with WindStyle after concerns are expressed by people and workers at the sites.

More and more building owners are realizing the importance of conducting wind engineering analyses prior to construction. While some major construction companies are starting to consider wind hazards for their larger projects, WindStyle is one of the few consulting companies that specialize in this area. As more people pay attention to their overall living environments, wind engineering is emerging as a critical consideration.

Field Research to Collect Model Data

When studying wind hazards, whether using CFD or a wind tunnel, three-dimensional geometry data is needed to construct a model. At WindStyle, a model consists of the building of interest and the surrounding buildings and features within a 300-400m (0.2 - 0.25 mile) radius. For a new construction site, this data is often provided by the customer. Unfortunately, the customer data is frequently only two-dimensional data. Engineers at WindStyle often go to the field site to obtain the information needed to describe the three-dimensional geometry. They also use available aerial surveys and photographs. With this data, a 3D wind engineering model is constructed in SketchUp.

For wind tunnel experiments, 3D data is shaped into a 1/300 or 1/400 scale model using plastic casting 3D printers and/or by hand. Wind direction and velocity are measured using small sensors located at the points of interest.

Process for CFD Simulation

For CFD simulations using scSTREAM, the CAD geometry data is output in STL format and read into scSTREAM where the mesh is generated and boundary conditions defined. Mesh size in the center of the model, where maximum resolution is needed, is on the order of 50cm (20 in). In the surroundings the mesh size is as large as 5m (16.5 ft). A typical model will contain ten to twenty million elements. Calculations are run using at least six computer cores in parallel. A set of simulations consists of running 32 different cases for each construction site, which covers sixteen different wind directions and simulates conditions before and after construction or construction modifications. Fewer simulations can be run when evaluating modifications if issues only arise for specific wind directions.

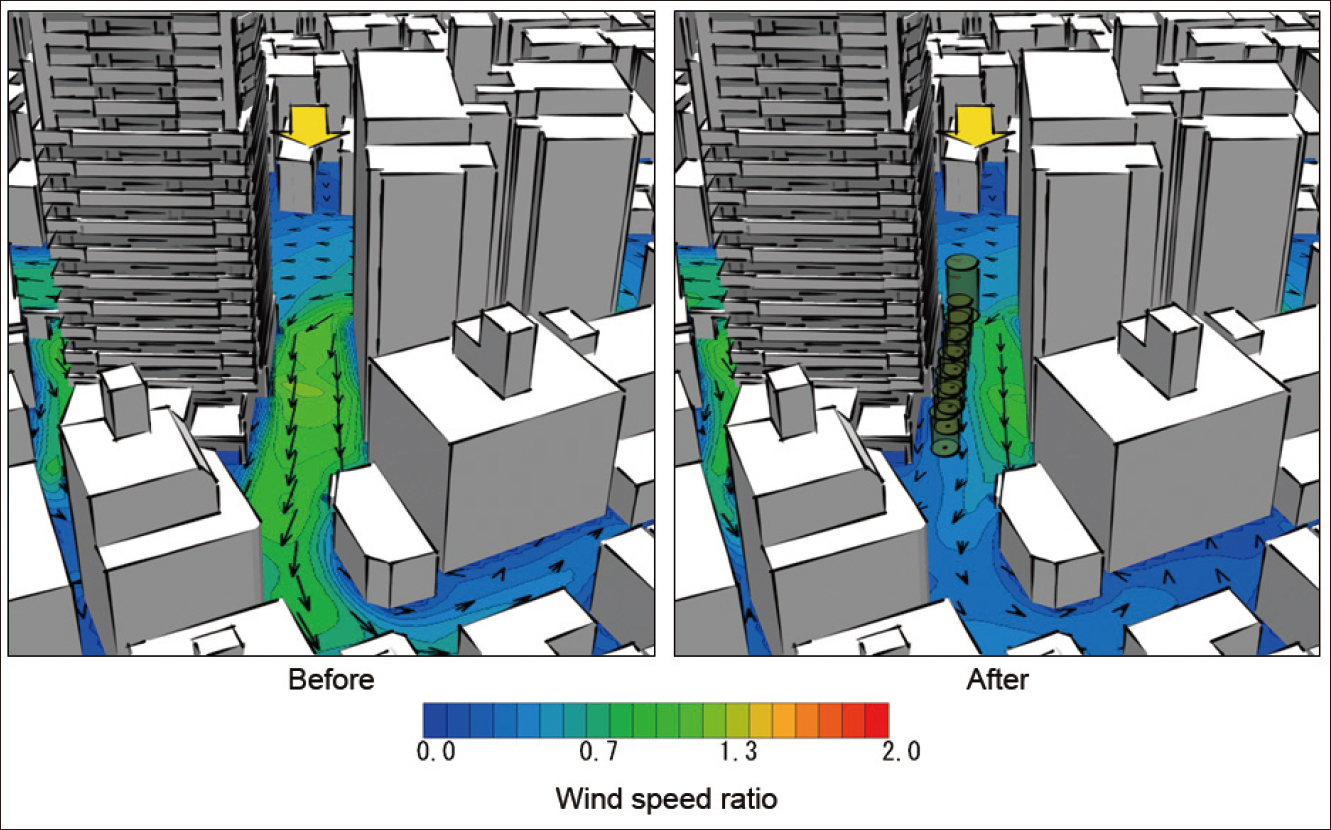

After obtaining the baseline simulation results, the architects, simulation and construction teams discuss countermeasures against potential wind hazards. These can consist of planting roadside trees or shifting/modifying the shape of a planned building. Another set of simulations is run to confirm the results before the recommendations are provided to the customer.

The Murakami Criteria are used to determine whether local wind conditions are severe enough to be a problem. The criteria rank the wind conditions in a local region by the frequency and strength of the wind gusts. The ranking is a sensory index based on wind engineering research. As the index increases, wind conditions become more severe. Threshold values based on experimental research are used to classify the severity of the conditions. WindStyle uses calculations from scSTREAM to evaluate wind conditions. They are able to use animations to visualize the air flow and show why the problems exist and how they can be corrected.

Making Full Use of the Software

When Mr. Matsuyama founded WindStyle, he evaluated several different CFD tools. He chose Cradle scSTREAM largely for its customizability. Mr. Matsuyama notes, "Because it [scSTREAM] accepted text-based inputs for boundary conditions, it made customization very easy. After a while, it was updated to become also compatible with VBScript, which made customization even easier."

One of the most important steps when performing CFD simulations using scSTREAM is precise control and adjustment of the geometry data. This can be a tedious and timeconsuming task, however, it must be performed in great detail because minimal differences in geometry can have very large effects on the outcome. Hence, this step is not trivial but must be critically tracked throughout the simulation process.

Mr. Matsuyama also has interesting thoughts about the importance of continually refining the mesh to improve accuracy. He argues that the methods used to assess simulation results and to translate the knowledge into improved designs are more important. "CFD results are more or less average values, and they do have a margin of error. In fact, we could make better use of the results by taking characteristics of the errors into account". This is a different perspective compared to the more traditional view of trying to eliminate all sources of error and to spend enormous amounts of time and effort trying to make the simulation results as accurate as possible.

Taking Advantage of Both CFD Simulations and Wind Tunnel Experiments

The key to successful design solutions is being able to take advantage of the strengths of the computer simulations and scale model wind tunnel experiments. In wind tunnel experiments, temporal variations in wind speeds can be quickly measured. It takes much less time to collect the data needed to characterize variation using a scale model compared to the time needed using its full scale equivalent. The difference is a factor of 60X. It may take ten minutes to collect data for full scale conditions but only ten seconds to collect the equivalent data in the wind tunnel. In the wind tunnel, the full set of characterization data consisting of sixteen different wind directions can be collected in an hour or two.

Another merit of wind tunnel tests is the use of "real" air for testing and the ability to reproduce literally every kind of flow condition. Though data is limited by the number of sensors used, both time dependent and time averaged measurements are very accurate.

The drawbacks of wind tunnel testing are the time and labor required to create scale models and the lack of wind tunnel facilities. A model can take as long as two months to build with a resultant cost of about $ 50,000 USD including one set of tests. Despite these drawbacks, experience with wind tunnel testing, data collection, and analysis is a major advantage.

Effect of roadside trees on alleviating strong wind (Tokyo)

Effect of roadside trees on alleviating strong wind (Tokyo)

In contrast, according to Mr. Matusyama, CFD simulations can start to "produce some results that can be presented to customers in one to two weeks." The time needed to build the model is shorter compared to constructing wind tunnel models. There is also no need to instrument the model or identify a test facility and schedule the experimental tests. Another major advantage of CFD is the ability to visualize the air flow using animation. In addition, design changes such as roadside trees or changing the size of shape of a building can be easily included in the model for little cost. The changes in the air flow can be easily visualized by comparing prior model results.

Mr. Matsuyama points out that the accuracy from the CFD simulations is not yet as good as the wind tunnel tests. Accuracy can be improved by refining meshes perhaps down to a few centimeters in critical regions. However, these very fine meshes increase the time required for the calculations and inhibit fast turnaround. This reinforces Mr. Matsuyama's intent to exploit one of the principal advantages of CFD, which is to calculate reasonable "average" values of the wind velocities. In the future, he hopes CFD can better simulate temporal variation, but remarks that "it is unnecessary to make CFD as accurate as wind tunnel tests in every respect. Rather, CFD is fast, good for visualization, and permits testing many di fferent parameters. Wind tunnel tests only test one set of conditions, although they are very accurate. We can take advantage of both."

Other Architectural Applications of CFD

Mr. Matsuyama emphasizes that there are other applications where CFD can be helpful in architectural design. One example is improving energy efficiency in single-family residences. The location and control of heating and air conditioning vents in homes are usually not considered with the intent of optimizing energy usage and comfort. They are largely a secondary consideration. Most vents are manually adjusted by homeowners who have little knowledge about balancing the entire system. Air flow simulations could be used to optimize vent locations and flow rates during the design of new homes.

A unique idea proposed by Mr. Matsuyama is harnessing wind velocity around tall buildings to provide wind power. By arranging the positions and shapes of buildings, the wind could be used to provide purposeful ventilation or used for power generation. "We are testing to see if we can simulate both the exterior and interior of buildings by refining the mesh down to 25 cm (10 in). As the computer hardware becomes more advanced and parallelization improves, the application range of scSTREAM will expand even more."

More Flexible Software Licensing System

As Mr. Matsuyama suggests, scSTREAM has significant potential in the field of architecture, especially as parallelization continues to improve for high-speed and high capacity hardware. However, he also expects software companies, such as Software Cradle, to be more flexible about how they license their software. According to Mr. Matsuyama, "CFD is not utilized in architecture as much as I thought it would be years ago. The cost of using the software in parallel processes might have become a burden for users". The speed of simulation has become much faster since Mr. Matsuyama started using CFD over fifteen years ago. But there is a limit in how much a single personal computer can do, and licensing costs for parallelized capabilities increase rapidly. Mr. Matsuyama envisions a day when he discusses designs with a customer while showing realtime simulation results being run on a cluster of computers. "There are many prospective simulations in architecture that require calculations using computer clusters. If it costs too much, people will not have the budget for it no matter how useful CFD is to that particular project". He believes that a change in the traditional software licensing system will enable more applications in different fields.

The Future of CFD Simulation in Architecture Industry

"It is easy to only see the negative aspect of a wind environment where wind hazards must be eliminated. But the positive side is thinking about how that same wind energy can be harnessed to provide low cost ventilation or even generate power. CFD simulations will be very useful for exploiting the positive side". Mr. Matsuyama adds, "This is a global topic. In regions of inconsistent power supply, people are still calling for well-ventilated buildings". He keeps his hopes high for CFD software and its future global applications. As the range of these applications gets wider and scSTREAM is improved more, opportunities for success will only increase for WindStyle.

WindStyle Corporation

- Established: December 2003

- Businesses: Research & Development in wind engineering, and related services

- President & CEO: Tetsuo Matsuyama

- Capital: 5 million yen

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of March 1, 2013 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download