Want to Know More! Basics of Thermo-Fluid Analysis 4: Chapter 1 What is thermo-fluid analysis? 1.3 How to make use of thermo-fluid analysis

1.3 How to make use of thermo-fluid analysis

Using thermo-fluid analysis in place of experiments in product design and development has the following advantages:

- Otherwise dangerous environments, e.g., high temperature, can be simulated safely and easily.

- Trials can be performed just with computers, without the need for prototypes or experiment apparatus.

- Distributions of instantaneous velocity and others can be obtained with no influence from measurement devices.

So far, thermo-fluid analysis may seem to have advantages only. Speaking as a developer and a vendor of software, however, fully replacing experiments with thermo-fluid analysis is not easy although that is where we are set out to. The reason for the difficulty is that the solutions we get with thermo-fluid analysis are approximate solutions involving the following errors:

- Errors from the approximation of physical models or the assumptions made in deriving the governing equations

- Errors in numerical calculations, e.g., rounding errors and truncation errors

- Errors due to the simplification of geometries

We can make analysis as close to experiments as possible through comparisons with experiments and adjustments. The more complex the problem becomes, however, the harder it becomes to do so. On the other hand, qualitative evaluations of solutions can be made relatively easily as we assume that each result can have the same level of error factors.

As we discussed, thermo-fluid analysis has its own advantages and disadvantages. Using thermo-fluid analysis with these understandings enables us to reduce the number of experiments and to grasp product performances early in the design phase, and hence allows for efficient design and development processes. It is also important not to take the results for granted and to be conscious about whether they are reasonable when we use the software.

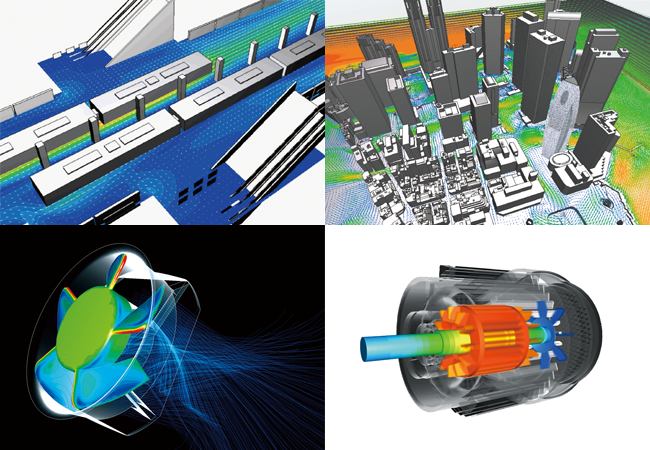

Figure 1.7: Examples of thermo-fluid analysis

About the Author

Atsushi Ueyama | Born in September 1983, Hyogo, Japan )

He has a Doctor of Philosophy in Engineering from Osaka University. His doctoral research focused on numerical method for fluid-solid interaction problem. He is a consulting engineer at Software Cradle and provides technical support to Cradle customers. He is also an active lecturer at Cradle seminars and training courses and the author of serial articles Basic Course of Thermo-Fluid Analysis.