BoostHEAT

Using scFLOW BoostHEAT Develops the World’s Most Efficient Boiler

Traditional residential heating & cooling systems are designed and configured with fairly standard systems and components. As a consequence, most of the systems on the market today have similar performance criteria, often well below the sorts of performance expectations required for the future. BoostHEAT was founded in 2011 when we recognized that this is an industry with huge potential for change. Increasing demands for more ecologically friendly products, accompanying changes in regulations, and the on-going end customer cost pressures means change is inevitable we believe. With our recent innovations around heat transfer, we are determined to revolutionise a traditionally very conservative market place, reducing customers’ ecological footprint as well as their utility bills. With over 5 years in the market now, and numerous awards and accolades, we are poised to make a significant impact in the boiler market.

BoostHEAT.20 20kW Boiler for domestic applications

At BoostHEAT we realised that by introducing higher performance, more industrial grade, capabilities to the residential market, we could start to reset expectations for more ecologically minded systems, and significantly differentiate our offerings. In short we recognized a significant business opportunity for an entirely new way of doing things.

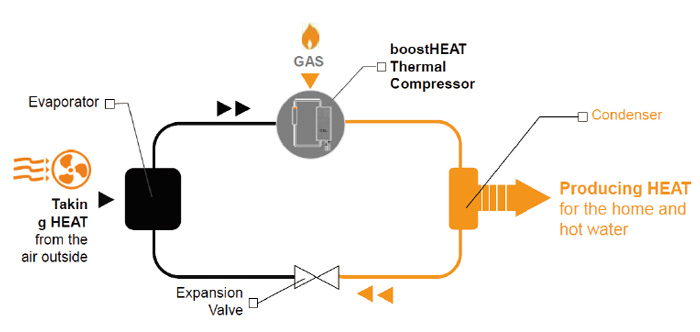

Traditional heat pumps are composed of four important elements in which there are fluid flows:

- Evaporator: Captures energy in the outside air

- Compressor: Provides the compression of the gas

- Condenser: Transfers energy to the heating circuit

- Regulator: Expansion valve to lower the pressure

In a heat pump, a compressor varies refrigerant pressure and temperature inside a closed chamber (see Figure 1). When connected to a heating circuit, and together with condensers and evaporators, it’s possible to capture the energy contained in the outside air and then transmit it to the heating circuit, thus heating it up. The same is true in reverse of course for cooling.

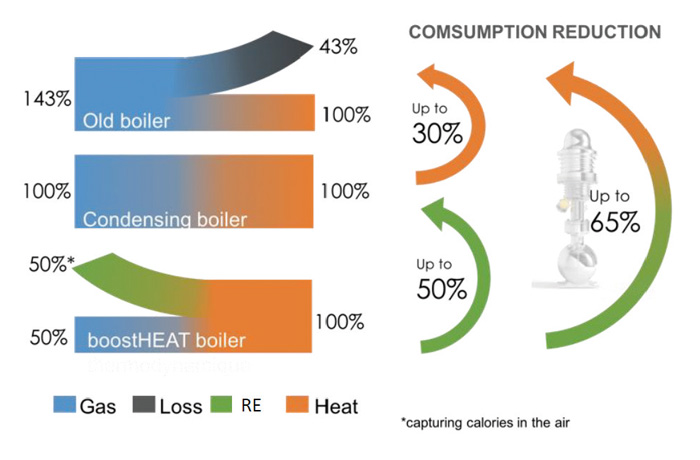

BoostHEAT’s innovation in our boiler design, for which we have multiple patents, is to use the energy produced by the combustion of gas (natural or propane) to carry out the work of the compressor. By combining the use of gas with the heat pump cycle, BoostHEAT’s regenerative thermal compressor, effectively merges these technologies to achieve up to 200% efficiency when compared to last generation conventional condensation boilers. The result of our research and development is that the boostHEAT.20, our latest product, is the best-performing boiler in its class. Its thermal compressor is frictionless (without oil) which makes it almost indestructible.

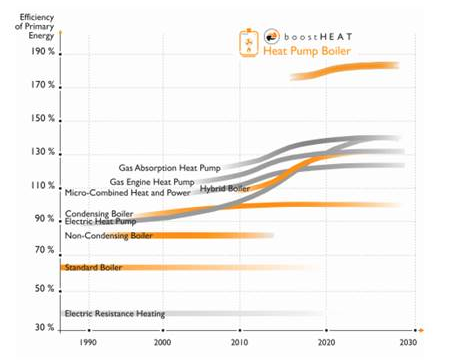

Our patented technology more closely integrates the idea of a boiler and a heat pump in one unit and is based on the Stirling Cycle such that our unique design of a regenerative thermal compressor can achieve a high temperature thermal compression cycle around 700 °C at a high pressure of 80 Bar while generating very high thermal outputs. Moreover, with no mechanical power transmission, our compressors can operate for 50,000 hours without any need to change oil or for maintenance, contrary to other standard technological solutions for engines and compressors. The net result is a new generation of heat pump that better utilizes the complete thermodynamic cycle, and produces a natural gas energy efficiency of up to 200% (see Figure 2). In independent audits our technology has scored very highly (see Figure 3).

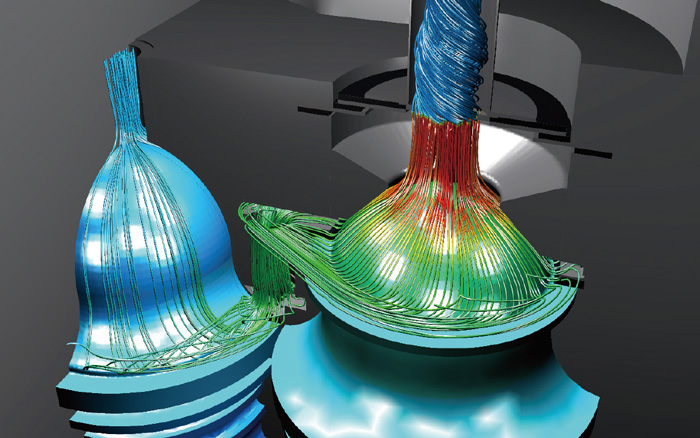

Obviously, innovation is key to our success. We have been using computational fluid dynamics (CFD) tools from MSC Software in the form of scFLOW (see Figure 4). It has been pivotal in our design exploration process because we originally set out to deliver the world’s most efficient boiler system that could optimize heat flux (the transfer of heat energy). New physics, new materials and methods, new designs, new manufacturing processes, not to mention the pressure of residential compliance regulations meant we had to gain as much insight as possible in the shortest period of time. Without access to CFD, we would not have been able to ascertain the complexity and performance of our new designs…

Employing scFLOW we worked through 20 key boiler design iterations, creating our ‘digital twin’. We then validated our CFD predictions against physical tests linked to our compliance needs. At each stage we’ve achieved higher temperatures and higher pressures, with increasing correlation to physical tests than previously. This momentum is important for us as a start-up company. CFD with MSC has helped us to achieve that.

What about the future? If you ask our team you’ll get a wry smile. We have successfully released our initial designs and we are taking orders. However, we are not done yet. I foresee more simulation, more multiphysics, more optimization and more innovation is on the cards. This is an exciting time for us as a company…

For more information on BoostHEAT the company and its products: https://en.boostheat.com/

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of November 15, 2018 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download