CAE Research Unit, Industrial Research Institute of Niigata

From left to right: Mr. Satoshi Katayama, Senior Researcher

Mr. Takashi Honda, Associate Senior Researcher

Mr. Tomohiko Muraki, Associate Senior Researcher

Dr. Hiroyuki Sugai, Senior Researcher

Applying MSC Cradle CFD (SC/Tetra) to Help Engineering Research and Development at Enterprises

The CAE Research Unit in the Industrial Research Institute of Niigata Prefecture has been applying computer simulations and structural analysis in order to provide technical support and R&D services for small enterprises located in Niigata Prefecture. Having first introduced CFD in 2010, they have actively applied CFD simulations for various research projects. This interview features their MSC Cradle CFD (SC/Tetra) application examples, and their motivation for using CFD.

Provide Technical Support to Enterprises in the District

The Industrial Research Institute (hereafter the Institute) is one of the public research organizations allocated to each prefecture across Japan, and provides wide-ranging support to small enterprises in each region. “In most cases, small companies have less capability for in-house R&D, quality control facility and manpower. This is why we offer help,” says Dr. Sugai (far right on picture)

Their primary tasks include technical support, consulting, testing, and evaluation. Over 10,000 requests are submitted to them every year. The Institute helps clients undertake costly and highly technical tests and evaluations at a reasonable cost. In cases where local companies need to use highly technical measurement equipment to undertake tests, and are short of skilled engineers with knowledge and expertise to operate the tool, the Institute also offers to conduct testing for the client on commission. The Institute has seven locations in total within Niigata, receiving 3,000 requests for test commissions, and 30,000 requests for equipment lease, annually.

Another crucial task is R&D, which includes collaborative projects with private enterprises. Collaborative research and product/technology development projects are funded by both private enterprises and prefectural government of Niigata. Subsidies and competitive funds are also acquired in collaboration with local enterprises, which in turn boost regional sales and employment.

The Institute also acts as a matchmaker for demand and supply, such as a manufacturer looking for a factory capable of processing components in specific manner, and a company looking for a facility capable of devising special heat treatment. The Institute maintains a database of approximately 10,000 companies in the district, detailing profiles of employed staff, their skills and proficiencies to match demand and supply. They are also actively engaged in product and new technology development. Having established three centers dedicated to promoting startup companies, the Institute has been advancing R&D in cooperation with laboratories in the area.

Various testing devices, measurement, and analysis equipment are facilitated in the Institute

CAE Research Unit Handles CFD Requests

SC/Tetra was introduced to the Institute by the CAE Research Unit (hereafter the Research Unit). As skilled users are required to conduct highly accurate analysis and validation, the Research Unit consists of engineers with CAE proficiency. “If each of us work separately and focus on our own tasks, we could end up being close-minded. By setting up the Research Unit where CAE engineers can interact and exchange ideas, we can improve our knowledge and experience. This also helps build our presence outside the Institute,” says Dr. Sugai.

CAE Research Unit has undertaken simulations of deformation processing extensively

The Research Unit excels at undertaking simulations of deformation processes. The reason lies in the nature of the local industry; many metal processing firms are founded in Niigata’s Tsubame Sanjo area (Figure 1). The Research Unit’s expertise in the area has been acknowledged and it received the Seventh Monozukuri Japan Grand Prix Award from the the Minister of Economy, Trade and Industry (METI) .

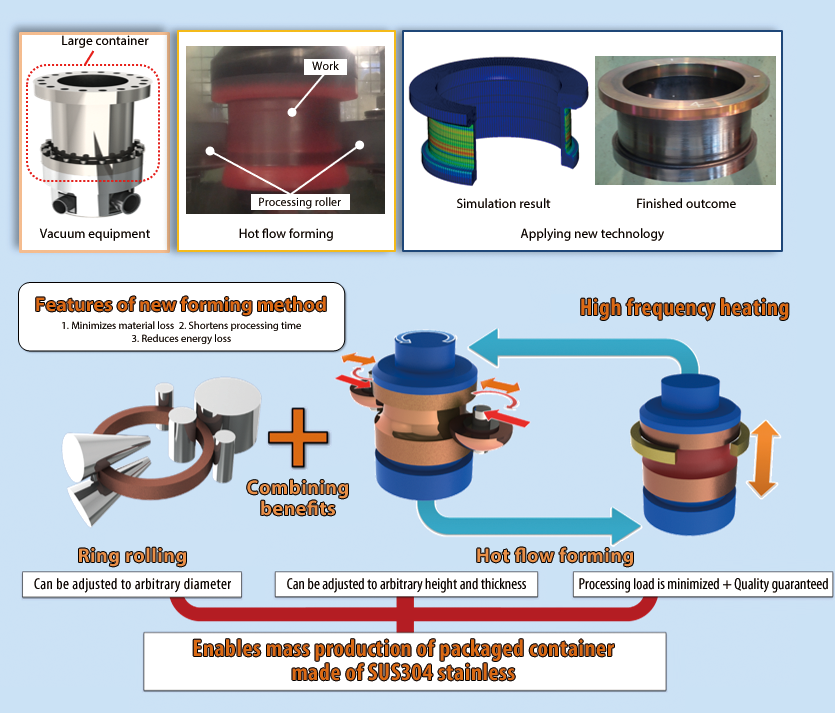

Figure 1: Development of new processing technology that enables handling wide-ranging geometry of

large stainless container for vacuum equipment (Niigata Industrial Creation Organization/ TANRAY KOGYOU Co., Ltd.)

In 2010, the Institute was asked to simulate a Stirling engine generator operated by exhaust heat. “Stirling engine uses temperature difference to generate kinetic energy. The company who came to us was aiming to develop a generator that is driven by low temperature exhaust gas,” says Dr. Sugai.

The Institute was asked to evaluate performance of the thermosyphon (a type of heat pipe, which allows thermal transfer of vaporized and condensed matter) and the heat exchanger inside the Stirling engine generator. The use of CFD was unavoidable for this particular case, but the Research Unit had no prior experience with CFD at that time. With the intention to ramp up on their CFD capabilities, they immediately started with the process of identifying and selecting a CFD software.

Requirements for CFD Software

The Research Unit first listed what types of analyses they were intending to perform and then determined software requirements. The candidate software were benchmarked against a set of examples and the results were used for software selection.

One of the benchmark examples was gas-liquid-two-phase analysis of inner thermosyphon space. They needed to evaluate liquid evaporation, movement and condensation of evaporated gas, and flow of condensed liquid. The Research Unit was hoping to identify thermal resistance, behavioral flow of condensed liquid, and pressure in each spot.

Another benchmark example was evaluation of heat exchanger performance. The analysis target was intersection of flow paths where flow of high temperature fluid joins flow of low temperature fluid. The Research Unit was hoping to identify thermal transfer efficiency and flow behavior (and degree of turbulence).

Having conducted benchmark tests, and determined software specifications, the Research Unit decided to adopt MSC Cradle SC/Tetra. Its trial version was provided with detailed operation manuals, and the Research Unit members managed to easily master the software in a limited amount of time. As soon as SC/Tetra full license was provided, the Research Unit members attained enough knowledge needed for basic operations at Cradle seminars.

Dr. Hiroyuki Sugai, Senior Researcher, R&D Center

Mr. Tomohiko Muraki, Associate Senior Researcher, R&D Center

Analysis Examples using SC/Tetra

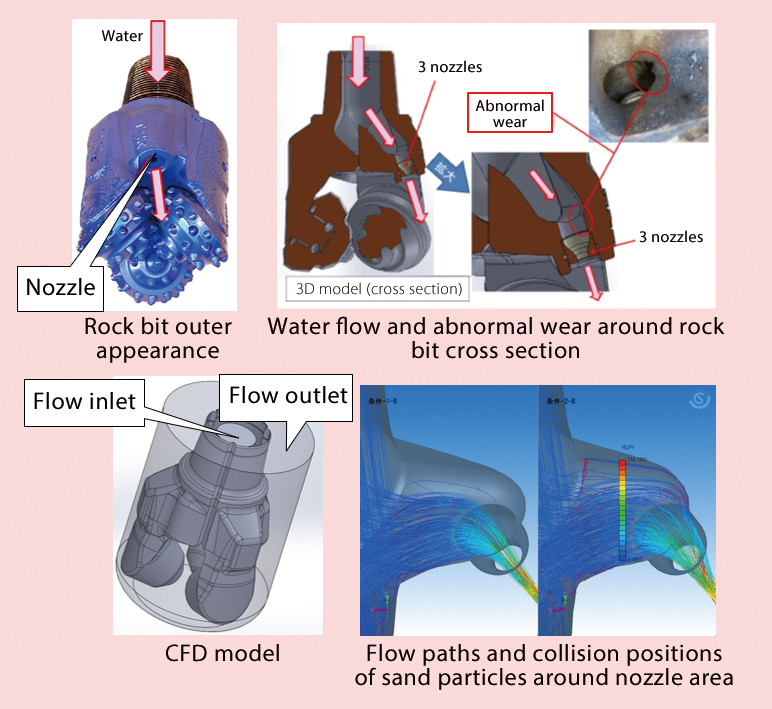

- Fluid Analysis around Rock Bit Nozzle (commissioned by TIX-TSK Corporation)

Rock bits are used to crash rock and dig underground natural oil and gas to develop geothermal wells. The equipment is highly heat resistant and pressure resistant. It is equipped with a nozzle to eject water to force out sand, which also induces a cooling effect. As water is ejected, small sand particles are entrained with the flow, leading to generation of abnormal friction. The degree of friction depends on the nozzle geometry and the rate of collision of sand particles.

Figure 2: Fluid analysis around rock bit nozzle (TIX-TSK Corporation)

In the CFD simulation, particles represented as sand were used to construct a model to calculate flow paths and collision around nozzle walls. Calculation results of particle collisions correlated well with the actual spots on the equipment, where abnormal wear occurred (Figure 2). As a result, CFD simulations were used to design the nozzle geometry to mitigate abnormal frictions.

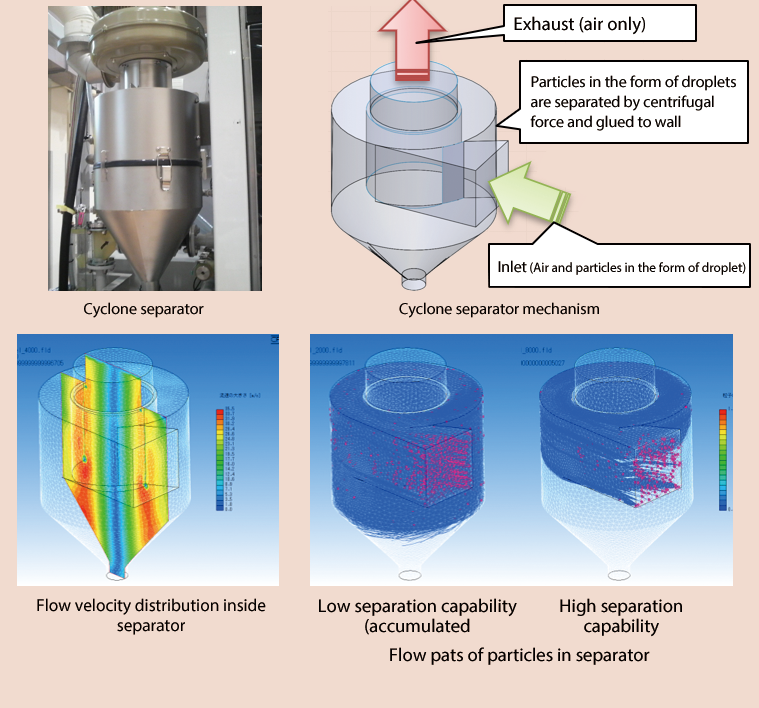

- Improvement of Separation Capability of Wet Blast Exhaust Cyclone (commissioned by Macoho Co., Ltd.)

Wet blast devices are designed to eject mixture of water and abrasives using compressed air. These devices are used to cover the surface of hard film, to debur, and to protect the surface of a precision machine. Blended droplets and abrasives are segregated by a cyclone separator from the exhaust air that is removed from the processing room. CFD was used to explore separation optimization and device miniaturization.

Figure 3: Improvement of separation capability of wet blast exhaust cyclone (Macoho Co., Ltd.)

The Unit used CFD to construct analysis models of cyclone separator. They then identified geometry of each part, flow rate of exhaust air, and effects on separation capability as a function of particle diameter in the intake charge. They discovered that geometry changes on cyclone tube and intake can enhance separation capability (Figure 3).

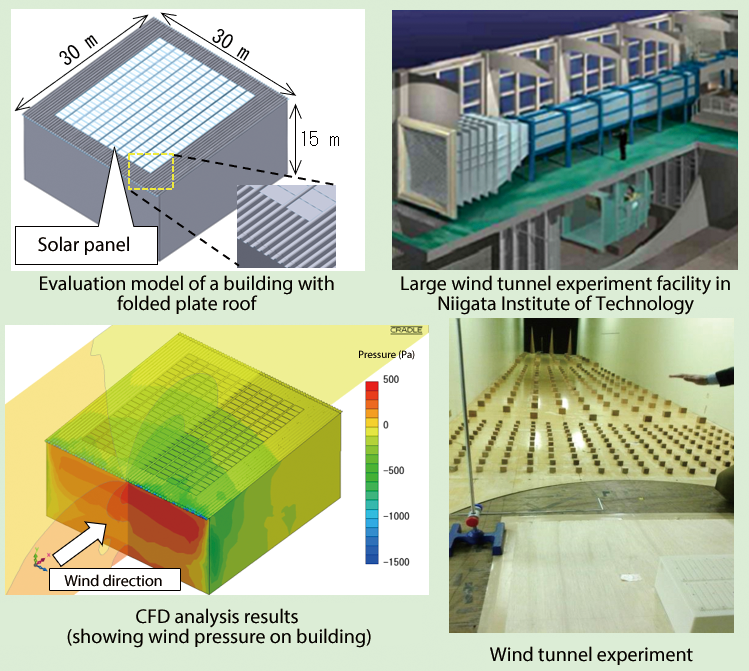

- Research on Wind Load Effect on Solar Energy Generation System and Load Minimization Approach (commissioned by SAKATA Manufacturing Co., Ltd.)

CFD analyses were conducted to evaluate wind load on solar panels installed on a folded plate roof (a type of metallic roof used for large buildings, such as factories, warehouses, and gymnasiums), and how wind load can be minimized. To undertake precise evaluations, wind tunnel experiments were executed in parallel to CFD simulations.

Figure 4: Research on wind load effect on solar energy generation system and load minimization approach (SAKATA Manufacturing Co., Ltd.)

CFD helped them identify the wind load acting on solar panel implemented on folded plate roof and understand the cause (Figure 4). The Unit also conducted wind tunnel experiments in cooperation with Niigata Institute of Technology and compared test results to CFD. The attained values were almost identical, which proved the accuracy of the CFD approach.

Satisfied with Highly Operable and Accurate Simulations

Dr. Sugai, who has used various CFD software including SC/Tetra for almost 20 years, gave the following feedback based on his experience working with Cradle.

- Quick Response

Dr. Sugai has been provided technical support from each CFD software vendor in the past, but is of the opinion that the support from Cradle is better. “For instance, Cradle answers to email inquiries on the day. They are also quick with function extension, which is a great benefit to us since we deal with evaluation cases that cannot be analyzed with standard functions,” says Dr. Sugai.

- User Friendly Interface

“Tutorials were easy to understand. I managed to perform analysis by simply following software instructions,” says Mr. Muraki, Chief Researcher in the Institute. He also notes that the software GUI is excellent. “Anyone can master Cradle, all you need is a little bit of CFD knowledge.” Mr. Muraki says that Software Cradle’s website articles are resourceful and help him explore new CFD evaluation approaches.

- Accurate Results

The Unit benefited from MSC Cradle CFD’s high accuracy when they were commissioned to evaluate flow rate distribution of flow melting pipes. The client that requested the project had already measured flow rate on an actual equipment but was keen to learn the capability of simulation as well. The Institute performed CFD analyses and attained results close to experimental values. “From this result, the client was convinced that CFD analysis results were highly accurate and decided that prototyping was only needed for the final validation phase. CFD capability to accurately evaluate a design is a great benefit especially to engineers involved in development, who have limited budget and time. I think that is why our clients often come back to us repeatedly for CFD evaluation requests,” says Dr. Sugai.

The Research Unit performing SC/Tetra analyses

Further Development with scFLOW Transition

“We have been told of the advantages of introducing scFLOW in comparison with SC/Tetra, such as minimized setting tasks and easy convergence without detailed settings. We can’t suspend on-going projects where SC/Tetra has already been in use, but we are planning a future transition based on an evaluation of simulation accuracy.

Although public research organizations have been instituted in each county across Japan, not all locations are equipped with specialist teams like the CAE Research Unit in the Industrial Research Institute of Niigata. In the world of manufacturing, where more rapid, accurate, and efficient development is required, CAE is expected to play an increasingly significant role. More public research organizations may introduce CFD in the future to support private enterprises. “We are 100% convinced of support quality, and we are hoping that Cradle will improve competitiveness in terms of pricing as well. We are currently focusing on CFD trainings and human resource development and planning to extend CFD application fields,” says Dr. Sugai.

Industrial Research Institute of Niigata Prefecture

- Established: 1914

- Locations: 7 locations in Niigata

- Operation: Business development at the Institute (types of industries include Machinery, Electronics, Software Development, Chemical, and Fiber), technical support (consulting, commissioned testing, equipment lease, and commissioned research), R&D (joint research and commissioned research), start-up support (through running of Startup Promotion Center), and resource provision (provision of technical information and reports)

*All product and service names mentioned are registered trademarks or trademarks of their respective companies.

*Contents and specifications of products are as of June 30, 2019 and subject to change without notice. We shall not be held liable for any errors in figures and pictures, or any typographical errors.

Download