Interview

New order | Old order

Tomo PE Jp Office

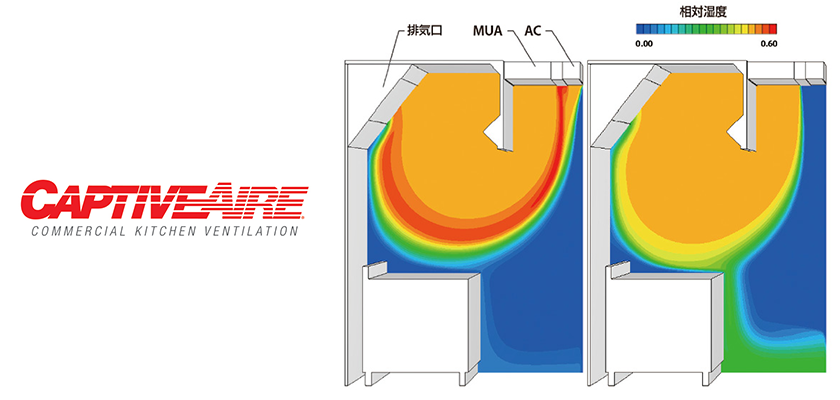

CaptiveAire Systems, Inc.

BoostHEAT

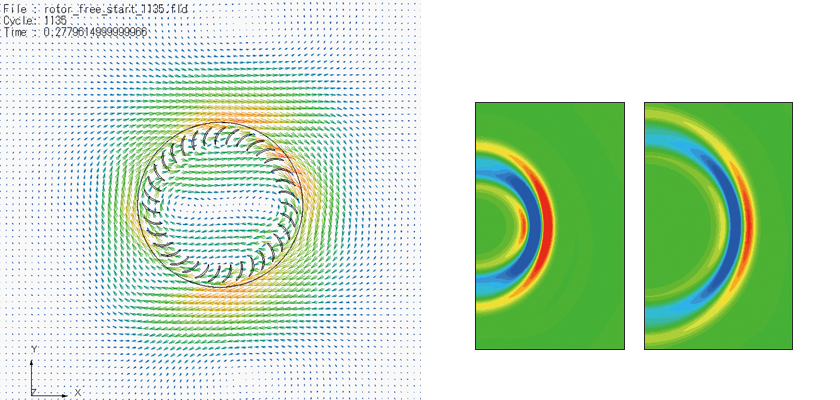

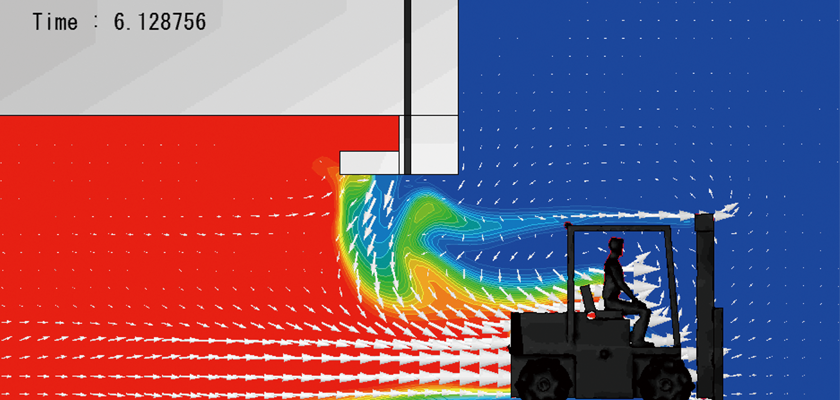

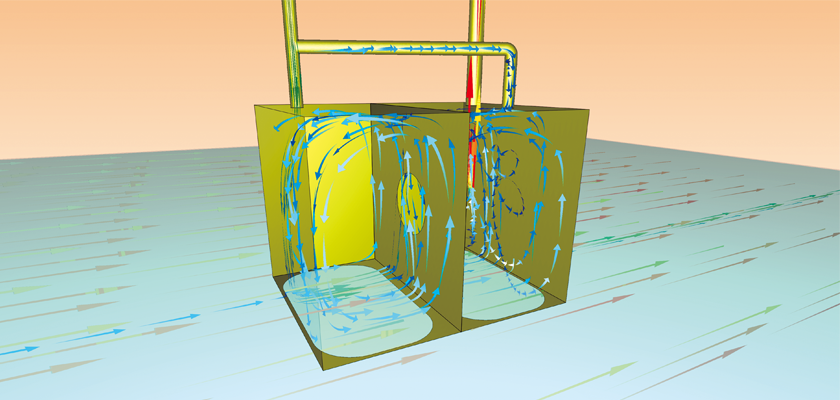

The Story Behind the Development of Cradle scSTREAM Moving Object Function

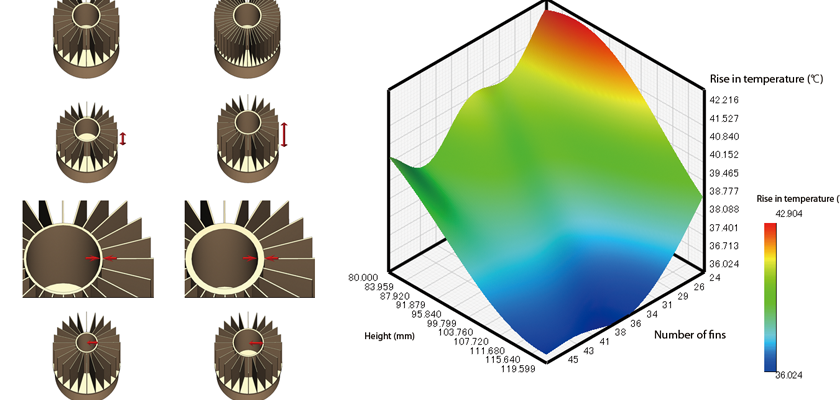

Optimization: Tool for Fast, Cost-Efficient Analysis

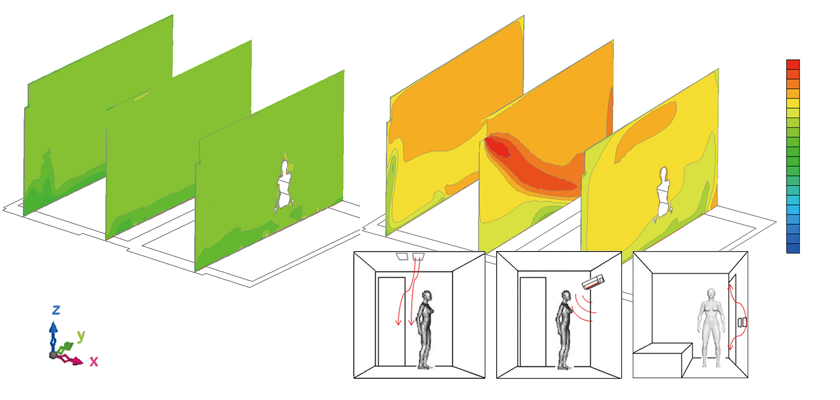

Thermoregulation Model JOS Function

FLUID TECHNO Co., Ltd.

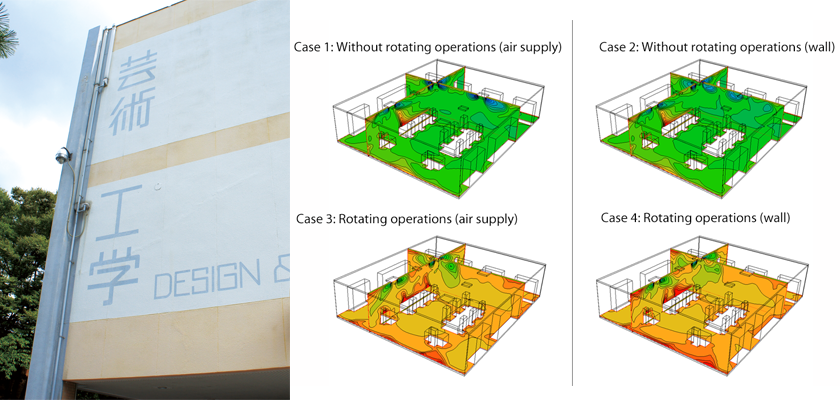

Tokyo University of Science (Department of Architecture, Faculty of Engineering)

Nagoya City University Graduate School

Picked Up Contents

Whitepaper

Turbocharging CFD with Katana

Unleashing cutting-edge computational fluid dynamics from Japan